Node adjoining roofing to the wall - do the right

So that the roof is firmly protected by a house from bad weather, its coating must be entirely impenetrable. The roof adjoining node to the wall and other systems is obliged to be carried out using materials and techniques suitable for the roof coating.

![]()

Vulnerability of adjoining nodes

The adjoining of the roof to the wall is considered one of the very wounded places of the roof - actually in places of the compound of the planes is collected by the wind garbage. It often keeps water that does not act on the joint and can destroy the roofing or material for waterproofing as a result of multiple freezing and thawing during temperature differences. Next to the walls in the winter, snow arrays are collected, which also increases the risk of leakage.

To ensure complete sealing of the roof, the rules of landscaping places of the adjoints should be provided on the stage of designing the structure. If such a building is built of bricks, a visor can be envisaged to a part of the brick over the coming roof and wall connection. Or when placing, the excavation is left, in what further the edge of the roof coating is started.

Sealing places of adjoins can be made using different materials. The technology of work is established by the roof view and the type of coating.

Two main types of adjoins are distinguished: upper and lateral. And in the other case, the butt strips of PS-1 and PS-2 are used.

Adjusting the roofs of profiled metal

When installing a coating for a roof from a metal profile, it is necessary to take into account that there is a gap between it and the sheer systems, which makes it possible to give the necessary air circulation in roofing cake.

The roof adjoining unit to the wall asks the use of special planks or aprons from steel based on a sheet. Installation of a single apron asks for the walls of the wall - along the line of the adjunct at height is not less than 200 mm, a groove is a depth of 20-30 mm. The edges of the apron are frozen by the repair sealant, after that the upper edge is put in the stroke,. The edge in the bottom is attracted to the roofing coating by self-drawing, endowed with neoprene or rubber seals to remove the falling moisture in the fastening place. Stroke, which is put on the upper edge of the apron, can be filled with cement mortar.

Using a double apron makes it possible to provide greater strength to the coating of the adjoining sealant. In this embodiment, it is not required to stick the wall. The top item is installed to the base of the dowels, then under it it is necessary to install an element that is located below, which with the help of the lock connection snaps on the upper apron. The lower apron is equipped with clemmers, which are attached to the roof by self-drawing. All connections are neatly separated by the repair sealant.

Ceramic and Bituminous Roof

If, in the form of a finite roof cover, a tile of ceramics is selected, the adjoining of the pitched roof to the wall is created using the corrugated ribbon from aluminum. A soft metal tape when installing repeats the coating profile, hot bitumen is poured into the seam (water insulation mastic on a bitumen basis), which firmly protects the joint from humidity.

With the help of corrugated aluminum tape and mastics based on bitumen, you can also use well-insulating the roof adjoining nodes made from bitumen tiles.

Adjusting the rolled roof

The adjoining of the flexible tile to the wall can be done in different developments. By tradition, the roll type material lies with an occasion of the sheer surface, where it is fixed with the help of the rail. This installation option can be used when equipped not only flat, but also the roofing type roofs.

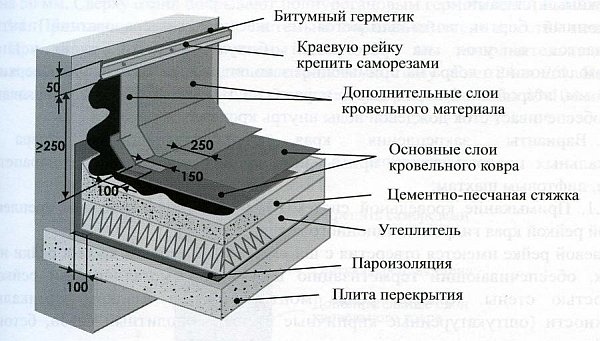

To ensure the strength of the adjoining assembly Ruberoid must be laid with a wall at a height of 10-20 cm. Wood slats, pressing a roll type material, is fixed with a dowel. The link of the rails with the wall should be well separated by a silicone sealant. The weak place of this system is the cavity under the rubber in the corner formed by the roof and wall planes. The roof covering may be improperly damaged in the performance of work on construction or when cleaning the roof from snow. To avoid this situation, the angle is filled with a triangular bar or an additional heat insulation layer.

A system that folds from a sheet of cotton insulator and a bar with straight angles of a small section, supplied at the insulation, can be applied. The resulting roller protects the runner from an unspere breakthrough and makes it possible to further insulate the adjoining.

When installing an insulated roof, together with the final coating on the wall, all layers included in the roofing pie, except the insulation.

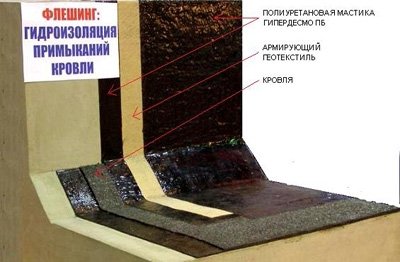

Flashing method

The roof adjustment device to the wall by the FLACHING method is considered today's, comfortable in applied by an embodiment of flexible tile. The technology of work involves the absence of flexible hydrophobic mastic, enhancing the compound of a layer of nonwoven material and another nanice of the mastic layer.

The short gap between the applying of the layers of mastic is obliged to draw up from 3 to 24 hours, no more.

With the correct installation made in this way the adjoining node varies:

- complete impermeability;

- flexibility;

- resistance to the effects of the external environment;

- resistance to temperature differences;

- reliability and longevity.

Flashing method makes it possible to ennoble the adjoining of rolled roofs of various types to walls made from different materials. The technology of work asks good preparation of surfaces, which we will apply material for waterproofing. First of all, the roof is cleaned of garbage, dirt and dust.

If the final roof cover is a rubberoid with mineral sprinkling, then the granules must be considered very carefully over the entire length of the insertion of the whole strip, which we will apply mastic. In another case, it is unrealistic to provide a maximum of a good adhesion of the roof coating waterproof. Based on synthetics, membrane materials should not only be cleaned of dust, but also to degrease the contact location with mastic.

In the case, when the roof is adjacent to the wall of the brick, it is necessary to look at the quality of the masonry. If the surface of the brick is very uneven, has destruction, it is recommended to launch it. Works on the waterproofing of the roof connection can be carried out only after the layer of plastering is completely drying. Before applying a mastic material, the surface is recommended to be separated by a fitting mixture.

If the plane roof is adjacent to the wall of concrete and iron, you need to make sure that there are no cracks and chips. When discovering, these are required to fill them with a repair sealant. All irregularities that perform should be carefully removed. Then the concrete surface is trimmed with a primer (primer mixture) on a bitumen basis. This will reduce the water absorption, will increase the knitting of the mastic to the sheer surface from concrete.

On top of the finished adjoining made by the Fleshhanka method, you can put a layer of mastic under the color of the roof coating, which will perform the appearance of the roof more beautiful.

Roofing adjunctions to walls and other systems are considered dangerous areas. Illiterate equipment, violation of the assembly technology inevitably leads to the decay of the waterproofing layer and the moisture in the space under the roof. Humidity accumulation with cotton insulation significantly reduces their heat insulation characteristics. Also, the humidity inciterates the rotation of the elements from the roof frame tree, as a result, in the future it will be necessary to spend considerable means for repairing the system of rafters with disassembling coating for the roof.