How metal is cut with gas

Autogenous metal cutting

The most common method for cutting metal today is autogenous, it is also called gas or oxygen. Its essence boils down to the fact that under the influence of a gas flame, the metal heats up and begins to melt, and under the influence of a jet of oxygen, it burns, making a narrow groove.

Acetylene, propane-butane, natural, coke oven gas are used as a heater.

Metal cutting can be classified depending on the desired end result:

- superficial;

- separating;

- spear cutting.

Surface gas cutting is used in cases where it is necessary to remove metal layers in order to form splines, grooves and other structural elements.

The separating view provides for a through cut to obtain the required number of metal elements, parts. Piercing metal to produce deep or through holes is called spear cutting.

Technological process

Regardless of the types of cutting, the technology for performing this process will be the same. Gas combustion provides a temperature of 1000 to 1300 o C, it is enough to melt strong steel. During this, a strong jet of oxygen is supplied, which reacts with the molten metal molecules, oxidizing them.

The result is a cut. Oxygen is supplied under high pressure. Often it reaches 12 atmospheres, such a jet, even without fire, can cut the skin.

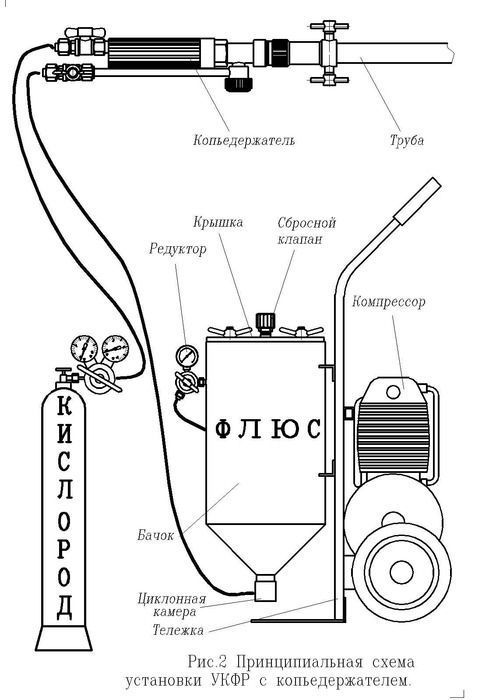

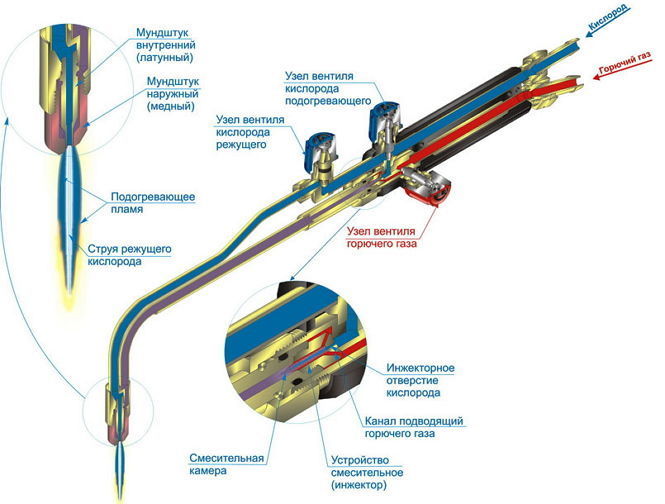

The structure of the cutting device is designed as follows:

- gas-burner;

- two balloons;

- mixer;

- pressure regulator;

- hoses.

A gas burner consists of a head with several nozzles, three is usually sufficient. A combustible substance is supplied through two side ones, and oxygen is supplied through the third, which is located in the middle. Cylinders are intended directly for gas and oxygen, depending on the volume of the intended work, cylinders of the appropriate capacity are selected.

To ensure one hour of continuous operation, an average of 0.7 m 3 of acetylene (1 m 3 of propane) and 10 m 3 of oxygen will be consumed. In general, the required amount of feedstock will depend on the density of the metal and the required temperature to heat it. It is possible to reduce propane consumption due to special nozzle attachments that fix the gas supply in a certain direction, the closer the supply is to the oxygen jet, the higher the fuel consumption.

Hoses are needed to supply oxygen and combustible substances from cylinders to the mixer, they are also called hoses. The material from which the hoses are made is two-layer rubber, between the layers is a frame made of cotton thread. Diameter - up to 12 mm, the possibility of operation at an air temperature not lower than -35 ° C.

The pressure regulator is necessary to provide different modes and cutting speeds. By supplying a smaller amount of fuel, it is possible to provide a low temperature, which is necessary for thin steel or metal of low strength, as well as reduce the consumption of raw materials.

Another important function of the reducer is to maintain a uniform pressure level. If the gas supply is interrupted during the cutting process, the metal will quickly cool and further processing will become impossible.

Metal cutting with propane and oxygen

Necessary equipment

Cutter P101

Cutter P101 The very first cutter was the P1-01 device, it was designed back in the USSR, then more modernized models appeared - P2 and P3. The devices differ in the size of the nozzles and the power of the gearbox. More modern manual installations:

- Change;

- Quicky;

- Orbit;

- Secateurs.

They differ in a set of additional functions and performance.

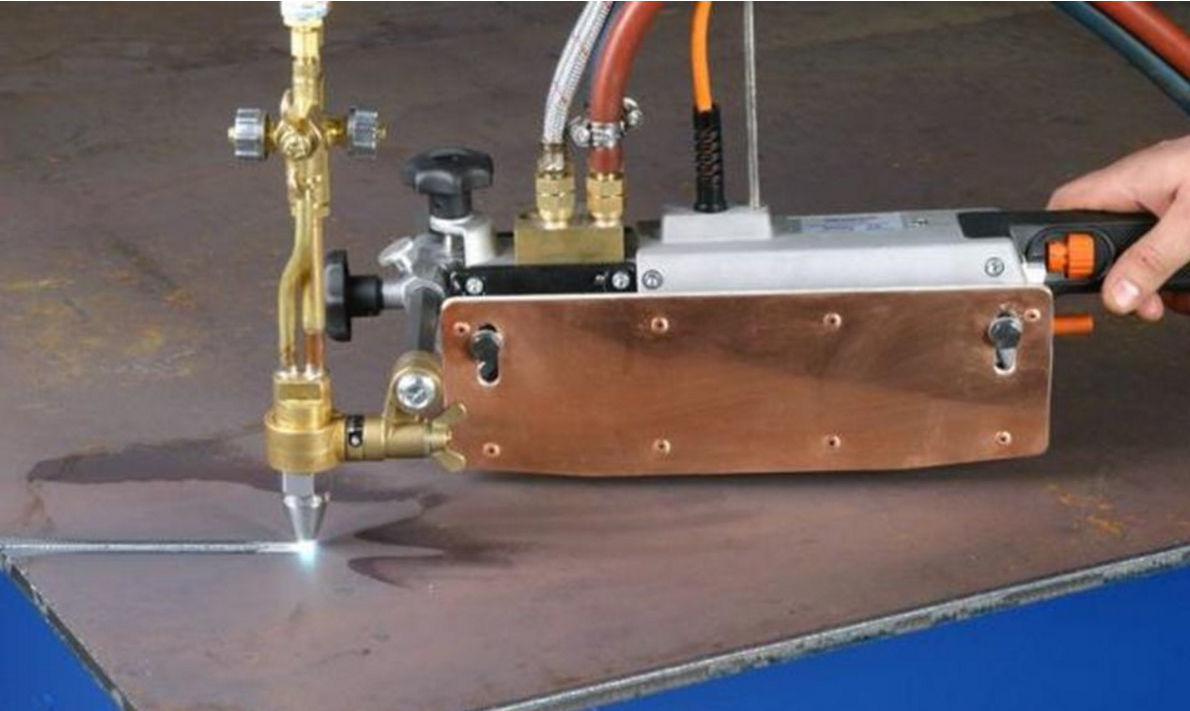

Quicky-E can carry out figured cutting, according to the given drawings, the speed of work reaches 1000 mm per minute, the maximum allowable metal thickness is up to 100 mm. The device has a set of removable nozzles to ensure the processing of metal sheets or pipes of various thicknesses.

This apparatus can operate using various types of combustible gas, in contrast to the prototype R1-01, which operates only on acetylene.

The Secator manual cutter has more improved characteristics in comparison with analogues.

With it, you can process metal up to 300 mm thick, this is provided by additional nozzles included in the kit, they are removable and can be purchased additionally as they wear out. Secator can perform the following types of cutting:

- curly;

- straight;

- ring;

- under the bevel.

The speed can be adjusted from 100 to 1200 mm per minute, and with the help of a built-in freewheel, the machine moves smoothly over the sheet of metal. The air-cooled gearbox ensures cleaner operation and reduces fuel consumption.

The above models are manual, that is, they are compact, controlled by the hands of the master. But for large volumes of processed metal, work with such

installations are inconvenient and inefficient. For industrial production, stationary cutting machines are used - this is, in fact, the same technology.

They are a machine with a tabletop in which a cutting mechanism is built. It is powered by an electric

compressor, which requires an electrical network with at least 380 V and three-phase sockets. The technology of operation of models of stationary cutting installations is nothing, but different from manual ones. The difference is only in productivity, maximum heating temperature, and the ability to process metal with a thickness of more than 300 mm.

Conditions for cutting metal with gas

Gas cutting of metal will be effective only when the ignition temperature of the metal is lower than the melting point. Such proportions are observed in low-carbon alloys, they melt at 1500 o C, and the ignition process occurs at 1300 o C.

For the high-quality operation of the installation, it is necessary to ensure a constant gas supply, since oxygen needs a constant amount of heat, which is maintained mainly (by 70%) due to the combustion of the metal and only 30% is provided by the gas flame. If it is stopped, the metal will stop producing heat and oxygen will not be able to perform the functions assigned to it.

Cutter work, metal cutting training

The maximum temperature of handheld gas cutters reaches 1300 ° C, this is a sufficient value for processing most types of metal, however, there are those that begin to melt at especially high temperatures, for example, aluminum oxide - 2050 ° C (this is almost three times higher than the melting point of pure aluminum), steel with a chromium content - 2000 ° C, nickel - 1985 ° C.

If the metal is not sufficiently heated and the melting process is not started, oxygen will not be able to displace refractory oxides. The reverse of this situation, when the metal has a low melting point, under the influence of a burning gas, it can simply melt, so this cutting method cannot be used for cast iron.

Safety

It is better to entrust metal cutting with a gas installation to an experienced specialist, since if handled carelessly, the consequences can be quite sad.

Safety precautions require the following conditions:

- good ventilation in the room where the work will be carried out;

- at a distance of 5 meters there should not be cylinders with gas and other combustible substances;

- work must be carried out in a protective mask or special glasses, as well as in fireproof clothing;

- it is necessary to direct the flame in the opposite direction from the gas source;

- hoses during the operation of the device must not be bent, stepped on, clamped with your feet;

- if a break is taken, then the flame at the burner should be completely extinguished and the gas valves of the cylinders should be tightened.

Compliance with these simple conditions will ensure safe and efficient metal cutting work with a gas machine.

Video: Cutter operation, metal cutting training