Foil insulation: self-adhesive thermal insulation with foil, its technical characteristics

Getting Started at home insulation, almost every wizard faces the problem of choosing heat-insulating material. Any thermal insulator must perform two functions: effectively prevent heat loss from the premises and resist the penetration of cold from the street. The tasks delivered well solves the foil insulation. About this material, its types and features, methods of application and installation will be discussed further.

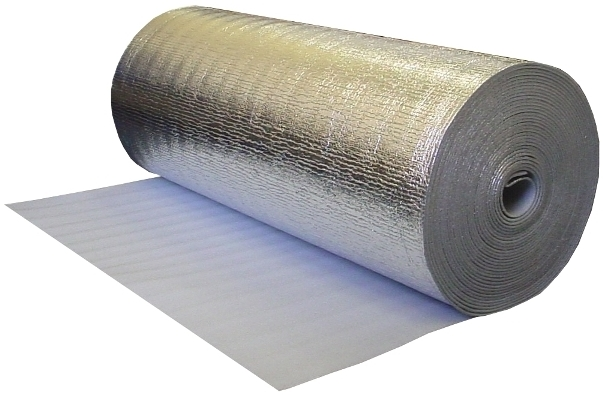

What is foil thermal insulation

The foil thermal insulation material is a two- or three-layer design with the main thermo insulating layer and one or two layers of aluminum foil.

The production process occurs by sintering the metallized layer with heatel under the influence of high temperature.

Positive properties

Heat insulation with aluminum foil has a lot of advantages, the main of which are:

- high indicators of thermal insulation properties due to the high reflectivity of aluminum;

- a smaller thickness compared to non-rich counterparts with the same thermal conductivity indicators;

- increased hydraulic resistance (thermal insulation is perfect for the insulation of basements, attics and other objects with high humidity);

- burning resistance (due to the layer of aluminum foil, such a heater can be used for thermal insulation baths, saunas, and other fire hazardous structures);

- wide scope of application.

In addition, the folgized insulation can be both rolled and in the form of plates. Due to this, the material is ideal for insulation of pipes, curvilinear surfaces and objects with a complex geometric shape.

The process of production of the insulation allows you to discourage an aluminum foil with almost any heat insulator. Despite this, the most sought after our compatriots are foil polyethylene foam and basalt wool.

This insulation is a rolled material from gas-filled polyethylene and aluminum foil. Basic specifications:

- standard roll width 1 m;

- the thickness of the insulation varies from 1 to 20 mm;

- the thermal conductivity coefficient is 0.022 W;

- application temperature from -60 ° C to +100 ° C;

- thermal reflection is 97%.

Despite the small thickness, this material is a good thermal insulator, hydro and parobarrier, and also thanks to the foil can perform the function of the heat transferser.

Application area

Most often, the foil-plated insulation of foamed polyethylene is used for internal repair work in private housekeeping, with thermal insulation of the floor, as well as as a substrate under floor coverings (parquet, laminate, etc.) due to installation features, this material is quite difficult to apply for insulation of walls and Ceiling.

In fairness it is worth noting that some manufacturers deliver self-adhesive gas-filled polyethylene on the domestic building market, which has become an excellent solution for insulation of vertical surfaces, ceiling and other uncomfortable places. In addition to the presence of an adhesive layer, self-adhesive insulation is no different from conventional foil polyethylene agent.

The main advantages of the material are highly efficient with the minimum thickness of the insulating layer, strength, environmental safety, ease of use and low cost compared to other insulation.

Only insulation, the use of material is not limited. Specifications made it indispensable for soundproofing of ventilation mines, air ducts, as well as sewer pipes.

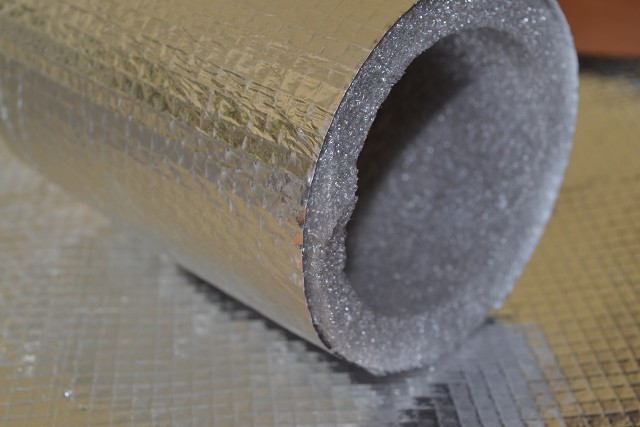

This material is pressed fibers made of basalt breed melts with a layer of aluminum foil. Foil basalt wool produced several types:

![]()

- in rolls, for insulation of horizontal surfaces (material density from 10 to 50 m³ \\ kg);

- in the plates, for thermal insulation of the walls (the density of semi-rigid plates from 50 to 90 kg \\ m³, rigid - above 90 kg \\ m³);

- in cylinders (sleeves), to isolate pipes.

Specifications and scope

The mineral wool insulation with foil is made with a thickness of 20 to 200 mm. The thermal conductivity coefficient is 0.03 W. Application temperature: from -200 to 700 ° C. The reflection of thermal radiation is 95-97%.

The scope of this material is quite extensive. Fungalized basalt wool insulation is used for external thermal insulation of residential, industrial, administrative buildings and structures, roofs, frontones, as well as to create a thermal insulating layer in refrigeration and freezer, tanks, for insulation of ventilation and air conditioning systems.

Benefits

The main advantages of the material:

- High heat insulation. The reflection of about 97% of thermal radiation makes this material with a highly efficient heat insulator.

- Fire resistance. Mineral wool with an aluminum layer refers to the class of non-flammable materials.

- Hydrophobicity. This type of insulating material does not miss moisture, which creates additional protection for structures from fungi and mold.

- High sound insulation properties.

- Parry permeability.

- Ecology.

- Easy installation.

Features of application and installation

Before starting work, you should know that the foil heat insulator is mounted by the aluminum side to the heat source. If the process of insulation is made indoors, then the metallized side of the material should look inside the room. When processing walls from the outside, the foil layer should look outside. This rule concerns both foamed polyethylene and basalt wool with a metallized layer.

When insulating pipes, it is necessary that the aluminum foil layer is from the outside. Such a location will prevent their overheating.

Using the material for insulation of the walls, it is necessary to leave the air gap equal to 20-25 mm. This will prevent the appearance of condensate.

Installation of foil polyethylene is made online. Installation of a mineral wool foil insulation - Vangest. The joints should be glued with aluminum scotch.

The insulation is installed on the metallized surface of the insulation, and the molding, drywall, OSB, chipboard, etc. is already made on it.

Foilized insulation is the best solution when it is necessary to significantly reduce the thickness of the insulation, without reducing its effectiveness. By purchasing such material, always pay attention to its quality and operating conditions.