Laying Metal tile: important points that need to be considered when working

Nowadays, the metal tile is one of the most popular roofing materials, which, thanks to its characteristics, much bypassed materials, widely used another five to years ago (for example, slate). The material presented here disassembles the subtleties associated with the styling of the metal tile. This question is now relevant for many, because the roof is covered with metal tile, it is quite possible and independently. It is only necessary to remember that this should clearly keep the procedure for laying the metal tile, which will be shown below.

Positive sides of metal tiles

The advantages provided by metal tile include:

- Ease of material - it ranges from 4 to 7 kilograms per square meter of coating area.

- Thanks to a rich color choice, a metal tile can harmoniously fit into the design of any home.

- The ribs of stiffness, as well as the thickness of the sheet provide high strength of the roofing coating. In addition, it will easily carry the temperature differences due to the maximum thermal expansion.

- The metal tile does not include malicious substances, so its heating does not represent hazards for human health.

But with all its positive sides, the metal tile possesses one rather significant disadvantage. It consists in weak noise insulation, that is, during a shower or hail, a knock on the roof of the house will deliver the inconvenience to those who live in it. Therefore, when laying this material, it is necessary to use additional sound insulators - usually it is glass or mineral wool.

Types of coating metal tile

This type of roofing material, as a rule, has a polymer coating. Metal tile is galvanized steel sheets, which are profiled by the rolling method. Zinc Provides protection of sheets from rust, and the polymer layer applied to them allows to prevent accumulation in the metal of static electricity. The width of such sheets varies in the range of 1.1 ... 1.2 m, the length is 0.8 ... 8 m, the height of the profile wave is 0.28 ... 0.75 m. The cost of the tile directly depends on the last parameter .

Such a coating has a warranty period of 15 years.

But when compliance with the technology of laying, metal tiles service life can be several decades.

Consider materials used for the manufacture of a polymer coating in more detail. These include:

- Polyester. With a low cost, this type of coating has high strength to mechanically effects and natural. The glossy polyester provides a roof of a beautiful shine under the rays of the sun, but is inferior in thickness, and therefore, according to the strength of the matte.

- Polar. This coating has a fairly high cost, but it ensures reliable corrosion protection. Saves Purally its properties in the temperature range from minus 15 to plus 120 degrees Celsius. The same properties have P50.

- Plastisol is characterized by the highest strength and durability of polymers. But it should be noted that in many countries it is prohibited due to low environmental safety.

- PVF2. This material is applied in the disgraced environment in terms of ecology. It is racks to the effects of chemicals and has dirt-repellent properties. Such a coating is extremely practical and has a high service life, but the cost of it is quite high.

Required conditions for high-quality styling metal tile on the roof

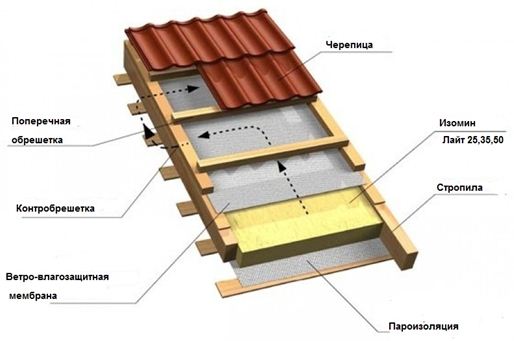

When laying this material, it is necessary to take into account that the roof slope must be at least 12 degrees. The boards used for the manufacture of the rafter system are set in increments of 0.6-1 m. The minimum cross section should be 15x5 centimeters. The size of the shell boards must be in accordance with the wave pitch.

Between the layers of isolation and tile, you need to make a gap in order to ensure high-quality ventilation.

Subtleties of mounting

Usually all the necessary guidelines that will be required when laying metal tiles are attached to the material when it acquisitions. If they are assisted, it is possible not only to understand independently with the whole design, but also make styling the metal tile with your own hands. In the work of work, you must pay attention to some nuances:

- When carrying out installation work, care must be taken - the movement on this material is allowed only by concave waves, otherwise it can cause damage. During work, avoid also shoes having a solid sole. The resulting chips and other construction trays should be trahane with a brush with soft fibers in order to prevent scratches on the material.

- Such roofing should be equipped with a grounding system.

- After three months, roofing screws that weakened under the influence of weather conditions should be tightened finally, after which the drainage system is mounted.

Technology Proper laying Metal tile on the roof

To properly implement this process, the following instruction will help you, as well as themed photos on the laying of metal tile:

- Preparation of the basis. Strengthening it in our case is not required, the laying can be made on a simple crate or even on an ordinary wooden chip. The sheets are fixed resistant to rust with self-draws. The shaft step is calculated in accordance with the size of the tiles, otherwise the screws instead of the crate board from time to time they will fall into the emptiness. In addition, the rafters do not need to be arranged over the windows.

- When laying a metal tile, do not do without a layer of thermal insulation (it often performs the function of the sound insulator, drowning the noise from the droplets of the rain or from the hail). The layer of vapor barrier material is laid on top of the rafter, then a layer of insulation with a thickness of up to 25 centimeters. They are covered with waterproofing film on top and fixed on rafters with bars. It should also be borne in account that moisture deposited on the film should only be drained into the drainage.

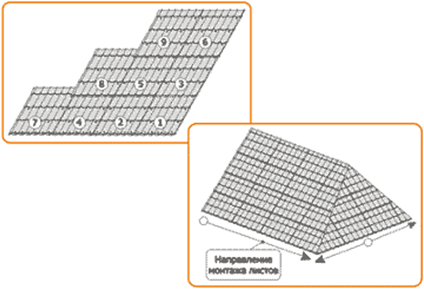

- Go directly to laying metal tires. Four first sheets are attached to the brand, but only one self-tapping screw is used. The lower edges of the sheets are then aligned on the eaves and are only then fixed completely. It is not necessary to save on the quality of the screws - it depends on how time the roof of the building will not need to be repaired.

- Installation of component parts. They are installed by the allen constituting for horizontal parts - 0.2 meters, and for those located under the tilt - 0.1 meters. In places of attachment of snowstores under the roofing material, bars are put on.

It is worth adding that by making a decision on laying the metal tile, it is better to purchase the entire kit for the equipment of the roof: from metal tile sheets and drain systems to crest and plugs. This will allow you to bring the roof of the house in a harmonious appearance immediately, and not to mount each component separately.

After the material is already purchased, it is necessary to make a decision who will deal with it. If you want to do everything yourself, you will help you in the article video on metal tile laying. If you prefer to resort to the services of roofers, then using read information, you can easily control the quality of their work.