Laying metal tile

Metal tile is exactly the material that is most often chosen to cover the roof of private developers. Such popularity is explained not only by good operational properties, but also relative simplicity of installation. Homemade masters planning to perform mounting on their own, can visually see how the metal tile is produced - there is a video on this topic on the sites dedicated to construction and repair.

If there is a desire to perform work on laying metal tile independently, you should first carefully examine all the steps of this process.

The fact is that on how correctly the installation was performed, the durability of the coating depends. Violations of the technology can lead to the fact that there will be signs of corrosion on the roof, and the coating will quickly come into disrepair.

Calculation of the number of materials

It is first necessary to decide how it is planned to work with such a material like a metal tile - how to lay, how much to make rows vertically? For this, there are simple calculations for calculating the roof of metal tile.

First we calculate the number of rows. To do this, you need to know the length of the roof cornice and the useful width of the sheet (this parameter is indicated by the manufacturer).

Example. Suppose that the length of the skate on the eaves is 5 meters, and useful (some masters speak - effective) sheet width 1.11 meters, the number of rows will be equal to five (5/1111 \u003d 4.50, rounded in a big one, we get five).

To determine the number and length of the sheets in each row, you need to know the length of the skate, measuring it from the skate to the cornice. To this magnitude, it is necessary to add a sink length (as a rule, it is 5 cm), as well as the length of overhearsow horizontally (it is equal to 15 cm).

The last value is taken into account because the metal tile laying technology provides for the laying of sheets with the allen.

Example. Suppose that the height of the skate is 6 meters, the total length of the sheets of metal tiles will be equal to:

6 + 0.05 + 0.15 \u003d 6.2 meters (provided that two sheets will be laid in a row).

Many manufacturers offer to chop metal tile sheets according to the customer. As a rule, the maximum possible length of the sheet is 8 meters, and the minimum is 0.75.

However, it is extremely inconvenient to work with sheets of a large length, therefore, if the skate length is more than 4-4.5 meters, the sheets are recommended to lay in two rows.

On the conditions of transportation and storage of metal tile

Successful laying of metal tires depends on the set of small details. And it begins with properly organized material delivery and providing normal conditions for its storage.

Here are a few rules that need to be observed during transportation and storage of metal tile:

- Loading packs with sheets in the car and their unloading should be made using soft sling.

- For the transport of metal tiles, it is necessary to use machines in which the body length is equal to or exceeds the length of the sheets.

- Other heavy loads are prohibited from top of packages with metal tile.

- Turn the sheets of metal tiles is needed in a vertical position, without allowing the formation of fesoms, bends and other deformations.

- In no case cannot move sheets from place in place by drawing.

- Consider how to lay metal tile for storage.

Metal tile can not be stored, putting the packs directly to the ground. If it is impossible to store the material in a dry room, it is folded under the sheds, building a lattice flooring from BRUSEV at the bottom.

A little about the composition of the "Pie" roof

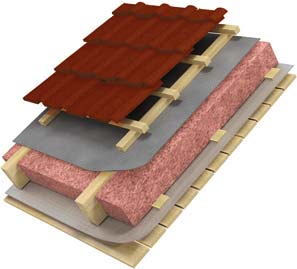

So that the roof can cope well with its protective functions, it makes it a multi-layer. The number and composition of the layers depend on the type of roof (attic, with a warmed attic, with a cold attic, etc.). As a rule, the roofs include the following layers:

- Roofing outer coating (in our case - metal tile).

- Obsek.

This is a design that serves as a frame, that is, laying is carried out - metal tile, as a rule, is stacked on a lattice crate. - Outdoor controlled metal tile. This is a design required for the organization of roof ventilation.

- Waterproofing.

- The internal counterclaim (the functions of this design are the same as the outer).

- Insulation (as a rule, this is mineral wool or polyurethane foam, but other options are possible)

- Parosolation.

- Inner roofing.

Preparatory work for styling metal tile

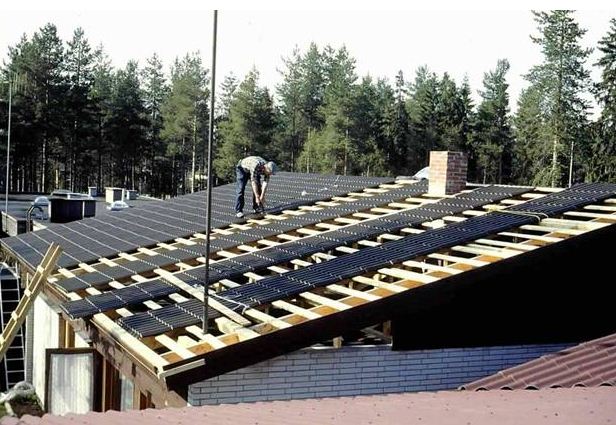

When using such a coating as a metal tile - laying the roofing material is made on the crate.

Consider the stages of the construction of this design.

- Brucs having a section of 50 mm are stuffed with a cross section of 50 mm that will play the role of an internal counterclaim. This design is built so that the clearance for airboring remains between the heat insulating material and the waterproofing film.

- Waterproofing is stacked on the inner control base and is temporarily strengthened with a construction stapler.

The film does not pull tight, but lay with a small provis. It is important that a 15 cm wide transition is made between separate panels. - On top of the waterproofing, there are external controls.

- Next, the instructions for laying the metal tile provides for the construction of the crate of the boards, which should be previously treated with antiseptic impregnations.

- The lower obrestena, located in the cornisic sweep, is made from the board with a cross section of 50 per 100. The main part of the crate is collected from thinner boards (32 per 100 mm).

The layout step depends on the wave step of the selected material. For example, for metal tile of the type of Monterrey, it will be 350 mm.

Special attention should be paid to the complex places of the roof - the inner corners formed by the skates, the yield of chimney and other adjoining.

Therefore, when installing roofing material in such angles, the question often arises how to lay - metal tile in such responsible places is placed on a solid crate, and under the roofing material there are such additional elements such as internal funds and aprons.

Laying sheets of metal tiles

Consider how to properly lay the metal tile on the ready-made crate.

To perform installation will require:

- Tool for cutting sheets;

- Screwdriver;

- A hammer:

- Marking rail (straight and long);

- Roulette and marker.

Use for cutting sheets of a grinder or another tool with abrasive circles is prohibited, since the protective coating is damaged during cutting, and the steel begins to rust quickly.

For this purpose, you can use hacksaws or scissors for metal.

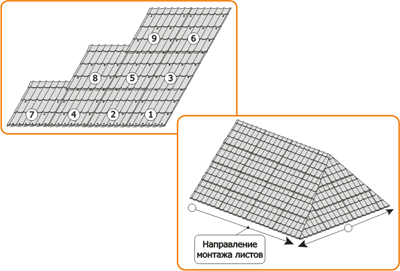

Adopted metal tile layout scheme as follows:

If laying sheets in two rows vertically, then the order of laying the metal tile is as follows:

- The first two sheets are stacked similarly to the scheme described above.

- The third sheet is placed above the first, with an adhesive 150 mm horizontally. The first and third sheets are bonded among themselves.

- The next (fourth) sheet is posted over the second and fasten it with the third vertical and with the second horizontal.

- They produce the final alignment of the obtained block and fasten sheets to the crate.

Adopted rules of laying metal tiles recommend using for fasteners only special roofing screws with rubber gaskets.

Screws are installed in the deflection (none in the case, not at the top) of the waves, the movement of the screws - through one wave .

Finishing stage

The final stage of the roof mounting is to install the outer elements of the roof, are attributed to them:

- End and skate slats;

- External endands (installed in the inner corners of the roof);

- External aprons (installed around chimneys and ventilation pipes);

- Antenna and ventilation outputs.

As well as the necessary accessories such as snowstores and roofing stairs.

Conclusions:

Installation of metal tile is not a particularly difficult task, but when performing work, it is necessary to show accuracy and clearly comply with the recommendations that the instruction gives. When performing these conditions, you can count on obtaining a durable, reliable and beautiful roof coverage.