Metal Cutting Technology Bulgarian

The angular grinding machine (USM), or Bulgarian, as it is customary to call it, an indispensable and universal tool in construction, is designed for cutting and processing solid materials. But this is one of the most dangerous types of equipment, therefore cutting metal with a grinder and other types of material requires compliance with all security rules.

For proper and clear work, you must purchase a tool suitable for the power and diameter of the cutting abrasive circle and functionality. You need to decide what kind of work is needed tool.

For home repairs, the masters can do a low-power grinder, and for professional construction there will be serious multifunctional equipment.

Types of angular grinding machine:

- professional;

- household;

- without pens;

- with one or more handles;

- different power: small, medium, large.

The low-power units are connected to a household outlet with a power of 220 V, powerful - connected to an industrial three-phase network, with a capacity of 380 V. In low-power Bulgarians, it often encourages the disk when cutting thick metals, it is dangerous that the device can break out of the hands, injured, or break the disk .

The Board of novice masters to buy a Bulgarian under a disk 125 mm with a capacity of 0.8-1 thousand W and the number of spindle revolutions 10 thousand rpm. This power is enough to cut iron.

It is used to cut metal, stone, glass, and with the help of this device make sprinkle, grinding and stripping. Pluging inpatient, it is easy to sharpen the cutters, knives of drill, etc.

When choosing a grinder, it is necessary to pay attention to it comfortably lying in the hand. This also depends on the quality and safety of work. If possible, choose a model with rubber handles.

Disc Selection

For each type of robots, a certain disk is assumed, with the desired diameter and thickness. Little diameter - 125 mm, and large or frequently used - 250 mm. The thickness of the cut and its depth depends precisely from the diameter of the disk.

For cutting metal, you must purchase a cutting disk with a thickness of 1 to 1.2 mm, for professional up to 2.5 mm. If it is assumed on a thin metal to make figure threads, then you will need a disk with a small diameter or spent.

Regardless of the size of the disk, the protective coating is placed - the casing, it is used when cutting the metal. During metal cutting, it is assumed to crash small particles to avoid damage with fine metal trimming install shield.

Basic security rules for working with metal

Before starting work, you must familiarize yourself with how to use the grinder, as well as with the features of safety. Even if the Master is not the first time in the hands of Bulgaria. Becoming for work should be collected, being as attentive, without unnecessary emotions, to avoid injuries.

How to cut metal? The main rules of this process:

- Specialist should be armed with protective glasses when working with the USM, take the shields, to avoid sparks in the eyes, small particles of metal.

- It is advisable to protect all parts of the body. In the hands it is necessary to wear protective mittens, not cotton, they are easily flammable.

- For cutting metal, the grinder must be removed nearby objects, especially faster.

- Must undergoing item must be fixed in a machine or visk. Do not hold her hand, do not clamp your feet.

- When installing a new disk, scroll it at the maximum speed, keep the grinder away from myself.

- If the disk is defective, he will be able to fly into small pieces and injured.

- The protective cover of the ESM should be adjusted, securely fixed. It is installed to protect the eyes from the departure of the particles.

- The master is obliged to remember when replacing disks or during rest, the device must be turned off from the network.

- Do not care for changing the disk while the Bulgarian is turned on.

- You need to navigate through the work area only with the turned off with a grinder.

- If the light turns off randomly, you must turn off the grinder to avoid unexpected inclusion.

You should not put the cutters instead of the disc, saws, it is strictly prohibited. It is necessary to comply with the rules of security and to minimize the possibility of injuries.

Taking into the hands of Bulgarian, it is necessary to remember that this is one of the dangerous tools tools. When breakdown, the ESM disk is able to escape from the hands and hit. When cutting it is possible to depart small parts, you need to foresee.

How to properly do with the aggregate? Additional security measures:

- After studying how to use the technique, you need to purchase cutting skills. To begin with, it is necessary to practice on unnecessary details.

- The heel of the disk is better and more efficiently cutting metal.

- When cutting metal, it is necessary to water the material with water, for cooling. This refers to any models.

- In more expensive, everything is automated, rotations occur easily, without a disc cluster.

- Do not turn on the technique at full power. This leads to rapid wear, as well as emergency breakdown.

- Be careful to wear of the cutting disk. The direction of work requires attention and scrupulousness.

How to properly cut the material? There are a number of supportive recommendations for the exploitation of the Bulgarian at home.

To avoid overheating, every five minutes you need to take breaks so that Bulgarian rested, for example, for 20 minutes. This is especially true of low-power models.

Aluminum soft and viscous metal. Cutting the detail of a large thickness, you need to drop kerosene. This substance is easily flammable, so it is necessary to comply with all safety rules to avoid fire.

For cutting fuscates and curved threads are used exhaust discs. After work, do not dispose of the worked out.

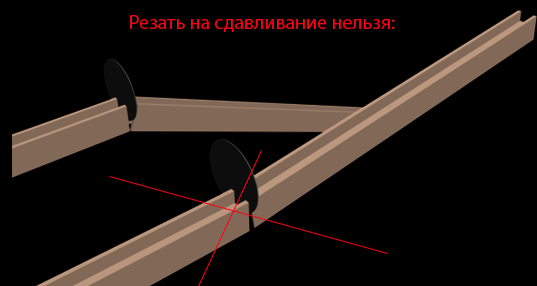

The corner is not cut in one reception, cut each shelf separately. To cut, a long tube requires a certain cutting technology, you need to start cutting around the hanging edge. If you start from the middle, the metal will join the disk.

Do not grind the material using the cutting sphere, its side part. There is a special grinding disk for this. Do not press on the disk, so as not to break it, as well as to avoid injuries. The lack of rapid rotation means the need to replace the disk.

Abrasive circles: Calculated, cutting, grinding, petal

It is necessary to pay attention, the cover protects from the split of the circle, so when the metal is sawing, if a thought appeared, it interferes, you should not remove it. It should be remembered that everything must be made extremely careful, for yourself, as well as for nearby.

Types of metals and features of their cutting

Cast iron, non-ferrous metals, stainless steel cut in special areas for a specific type of material. Disk information is easy to find on its side part.

It should be noted that stainless steel cannot be cutting with a regular disc. The disc contains substances that destroy the protective film of this material. In the future, corrosion will be formed in the context.

Cutting discs differ from each other not only with a diameter and thickness, but also more than the composition of the filler. The superproof material is added to the discs for cutting alloy steel. The soft bundle is added to prevent overheating of the cutting element when used in the cutting of aluminum and different types of non-ferrous metals.

Thin proflists and tin are cut with steel discs with a small tooth. Thick, respectively, thicker discs.

Special spheres are used for grinding. When the casing is removed, but necessarily in protective glasses. The work is performed smoothly throughout the surface.

Remember, working with a grinder or an ushm requires special attention and skill.