Modern Roofing Materials for Coating Flat Roofs - Photo and Video Overview

For residents of Russia is associated primarily with production, administrative buildings and commercial facilities, because the traditional architectural forms of our country are associated with two-tie and three-piece structures. Adherence to triangular roofs is due to a harsh climate with a large amount of precipitation in winter and summer. The primitive coating that was available in the arsenal of builders did not cope with the volume of the incoming fluid, leading to leaks. In this article, we will look at modern technological and durable materials used for a flat roof.

The creation of a flat roof resembles the manufacture of a multilayer pie, in which roofing materials are imposed on each other to provide the best waterproofing. The coating of this type may include 3-9 layers laid in a certain sequence. However, the cost of arrangement of this type of overlapping is 3-4 times cheaper than the construction of scantal analogs due to savings on lumber used to create a rafter frame. The structure of flat roofs is the following structure:

- The base treated with a special primer. Concrete slabs or wooden flooring are fed as a base for flooring flat roofs. They are pre-cleaned from pollution and garbage, aligned, all cracks are closed on the surface. Then the primer layer is applied, which makes the material structure smoother and increases adsorption.

- Screed. The pre-prepared base of the flat roof is poured a layer of a concrete screed to perform a flap. The flap is called the process of creating a slope to ensure the transfer of rain and melt water to the drainage funnels.

- Heat insulating coating. To prevent heat loss, the plates of the insulation are placed on the concrete screed. Usually used glass gamble, basalt fiber or extruded polystyrene foam. Some technologies make it possible to make a pile, using flowing thermal insulation materials, including clay.

- Screed. After the thermal insulating coating of the flat roofs, one more layer of screed, which protects the insulation from mechanical damage, deformation and wetting.

- Waterproofing. After the second layer of the screed, the waterproofing coating is laid, to create modern roofing materials, laid in several layers. Flat soft roof is made from bitumen, polymeric and bitumen-polymer coatings mounted by moving or fill.

Note! Flat roof saves funds spent on the construction of the house, and also provides the ability to use additional space. The operated overlap can be equipped as a summer cafe, a greenhouse, to arrange a swimming pool in it, break the lawn or even grow vegetables. In addition, the popularity is acquired by the projects of "smart homes", independently providing themselves with electricity due to solar panels installed on flat roofs.

Methods of installation

The device of a flat roof, which uses technological materials to strongly depends on weather conditions, humidity and base states. Projects of private houses with such a type of overlap are becoming more popular, so manufacturers seek to introduce new types of coatings, which require less strength, time and skills. Now in the construction market there are roofing materials suitable for roofs of any types, a variety of square. The most common covers are:

Important! The efficiency and service life of a flat roof depends on the compliance with the laying technology of roofing material and proper base preparation. In many cases, the filtered materials can be mounted on directly on the old roof coating, without dismantling it, which greatly simplifies the workflow.

Bituminous materials

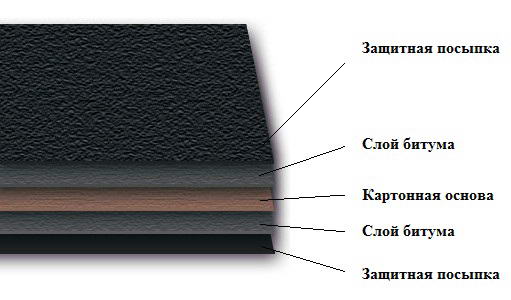

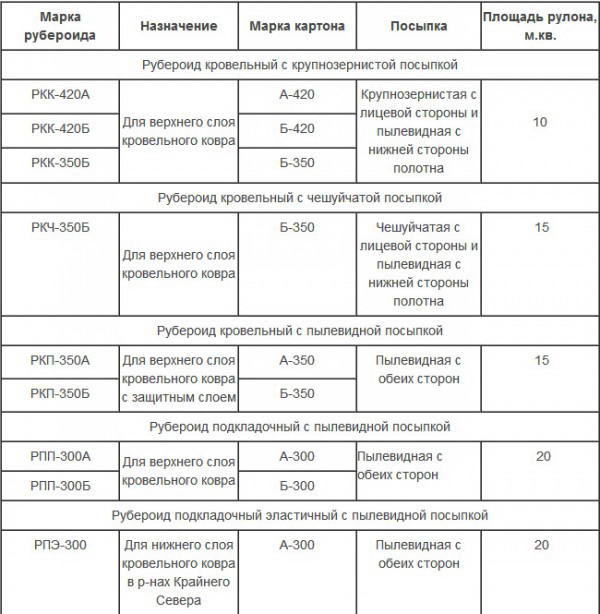

Bitumen rolled materials used to cover flat roofs include tol, rubberoid and pergamine. They are produced by impregnating roofing cardboard with bitumen mastic, which is a product of refining oil industry. These are the materials of the past generation, which have a small lifetime, low strength and poor resistance to low temperatures. From above and below, they sprinkle fine-grained, dust-shaped, coarse-grained or scales for protection against mechanical damage and sticking the layers inside the roll. For the construction of roofs, bitumen materials of the following types are used:

- Lining. Bitume-based lining materials are used to create inner layers of roofing pie and waterproofing foundations. They are manufactured on the basis of cardboard with a density of up to 370 g / sq. m. Lining products cost cheaper, however, has less durability and durability. The service life of this type coverage is only 2-3 years.

- Roofing. Bitumen-based roofing materials are used to create upper flat roof layer, as they are more dense, durable and resistant mechanical damage. For the production of such products, cardboard with a density of 350 g / sq. m and coarse-grained stone sprinkle. The service life of roofing types based on bitumen is 5 years.

Note! To create a high-quality and durable coating for a flat roof, we set 3-7 layers of rubberoid or roofing: 2-3 lining and 1-4 roofing. Materials are placed in disintegration so that the joints of different layers are located in different places without falling on each other.

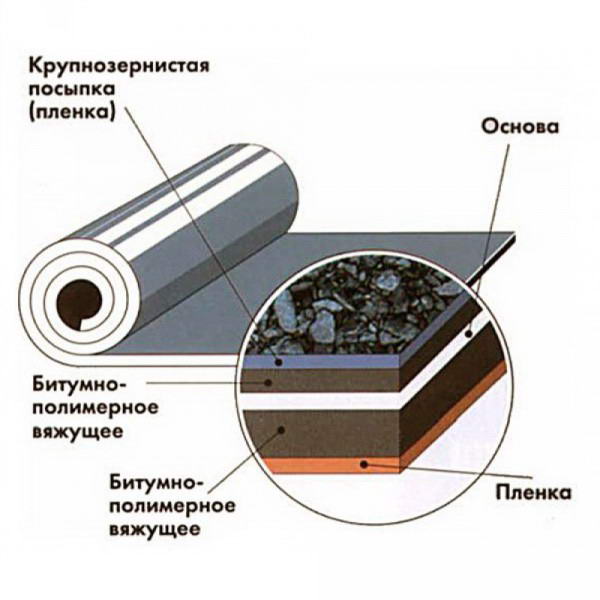

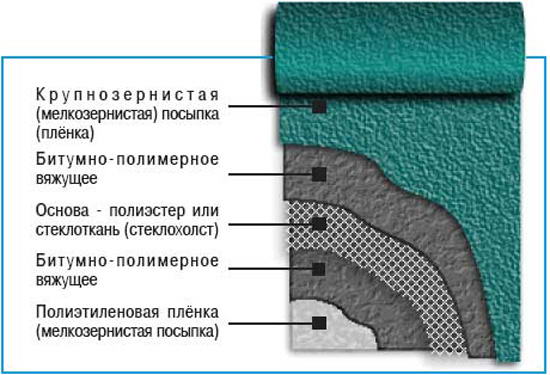

Polymer materials

The new generation of the installed materials manufacturers were developed for soft roofs, taking into account the shortcomings of earlier analogues. They solved the problems of low resistance to temperature drops, a short term of use of coatings, unsatisfactory strength. The result of research and application of the latest developments was the production of materials from synthetic rubbers and polymer resins. From the coverings for the roof based on bitumen, they differ:

Note! To mount the polymer material, you do not need to melt the bottom layer using the gas burner. Stacking is performed using hot air or adhesive tapes. The soft surface, heated by the construction hairdryer, is securely glued to the prepared base.

Video instruction