Calculation of distances between raps

The distance between the rafyles is a fundamental parameter on which the strength and reliability of the roof structure depends, its service life, the possibility of using certain roofing materials.

The strength and service life of the roof depends on many factors: the quality of building materials, climatic conditions, the reliability of the crate.

But the carrying roof design is a foundation on which the whole design is resting.

The rafter system must be accurately calculated, competently mounted and reliably protected from the devastating external influence.

General scheme for calculating the rafter step

The rafter system is the supporting structure of the whole roof. It consists of rafting legs, vertical racks and inclined pods.

Each rafter is located at a certain distance from the following - this distance is called the "Stropy step".

It is from it that the strength of the roofing structure is dependent, the maximum allowable load per square meter and materials that can be used for roofing works.

According to GOST, the minimum allowable value of the rafter step is 60 cm, mean - exceeds 1 m.

To determine the approximate step, you can take advantage of the following formula: D / (D / M + 1), where D is the length of the roof from the skate to the skate, M is an approximate rafter step.

All results obtained must be rounded to the nearest larger. Obviously, such a formula serves solely for approximate calculations.

To determine the exact size of the step, the following factors must be taken into account:

- own weight of the rafter system, i.e. the materials from which it is made;

- the weight of the material you plan to cover the roof;

- the weight of additional insulation, seals, hydro and vapor barrier systems;

- weight of the crate;

- the weight of finishing materials attic;

- climatic loads (wind, snow accumulation).

In addition to the above loads, the roof must withstand weight, at least one adult, so that in the case of repair or installation of the antenna, the installer could climb on the roof without fears.

If you are planning to install a chimney pipe, then its location must be initially included in the calculations so that in the future it does not need to remove part of the roof and install additional support points.

Single and duplex roof: Difference in rafal systems

For a single roof, we simply build a rafter system. Most often, the rafters are placed directly on the crown, without the use of additional supports and supporting structures.

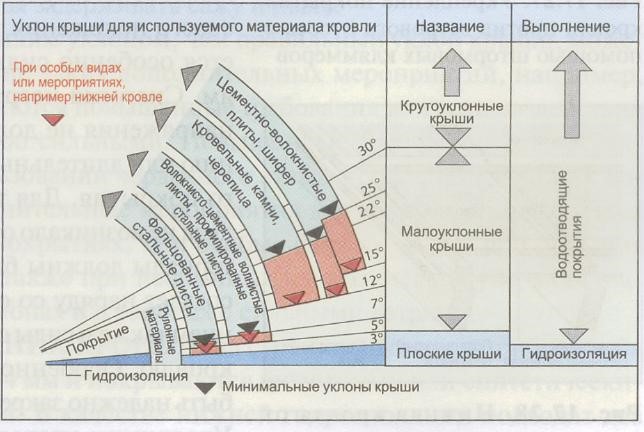

That is why the maximum angle of inclination of a single-table roof is limited to 30 degrees: the absence of additional bearing structures and supporting beams means that the entire load falls on the walls of the building and the foundation.

The optimal angle of inclination is 15 - 25 degrees. The maximum allowable length of the span of the rafter does not reach 6 m.

When erecting a single-sided roof, be sure to take into account the wind direction and the possible additional load on the weight of the snow accumulated on the roof.

For houses located in the regions with strong winds and a small amount of precipitation, you can adjust such an angle of the slope at which the roof is cleaned of snow due to the impacts of the wind.

The bartal roof is a system of two sloping rods connected by a skate. One of the main advantages of such a design is the possibility of a more uniform distribution of the load between the rafter system and carriage walls of the building.

In addition, the double framework allows the rafters to be opened on top of each other, which gives it additional strength.

The total strength of the roofing structure increases with the approach of the corner of the row to 45 degrees. It is such a tilt that is considered optimal for regions with abundant precipitation.

When increasing the angle of inclination, on the one hand, stability is significantly increased, so you can take a larger rafal step.

On the other hand, the roof sailboat increases, therefore, for windy regions, the optimal angle of inclination does not exceed 20 degrees.

Slinge system under slate

Despite the emergence of a large selection of modern roofing materials, the classic version - slate - is still very popular, mainly due to the cheapness and ease of installation.

The distance between the roof rafters for slate is calculated taking into account the characteristics of the material: slate is fragile enough, but at the same time it is capable of withstanding large weight loads.

The permissible range of the rafter step under slate - from 80 cm to 1.5 m. Most often use the average step length, 120 cm.

Since the slate itself weighs quite a lot, the material for the supporting structure must be chosen durable, for example, bars with a cross section of at least 75 mm 150 mm.

The length of the rafter step and the thickness of the crates is interrelated: the more stronger crate you plan to install, the less step, and vice versa.

The slate sheet has a standard length of 175 mm, the shade step is selected in such a way that each slate sheet has at least three support points (one in the center of the sheet and two closer to the edges).

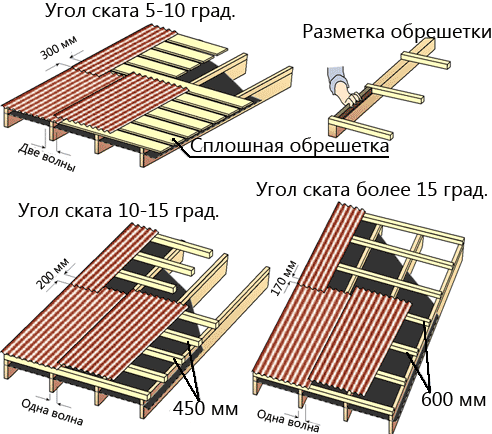

The shadow step depends on the degree of the roof slope: for a canopy of a single or twin roof, 63 - 67 cm is enough. The minimum gap for the steep roof is 45 cm.

You can install the exact length of the rafter step under slate, only by producing accurate measurements and calculating the total weight of all roofing materials.

Do not forget to take into account meteo conditions (the ability to accumulate snow, strong wind gusts) and the load of additional equipment (antenna or chimney pipe). If the attic will be equipped with attic, then consider the weight of the insulation.

Nuances of the system for metal tile

Metal tile is one of the most popular roofing materials on the market. She is unpretentious in circulation, durable, looks beautiful.

In addition, metal tile is one of the easiest roofing materials (only 35 kg per square meter), it can be laid on a sufficiently light support, thereby reducing the load on the walls of the building and the foundation.

The average distance between rafters for metal tile is 60 to 95 cm for a two-tie roof with a slope of 20 - 45 degrees.

The size of the bars is chosen with the insulation and waterproofing materials. For a simple roof of metal tile, a sequence of 50-150 mm is enough.

But in most cases, to create an attic roof under metal tile, you will have to put the insulation with a thickness of 150 - 200 mm.

Taking into account the weight of the insulation, the rafter system should be more durable, the recommended size of the BRUSEV increases to 200 mm by 50 mm.

When calculating the distance between the rafters, consider not only the length of the sheets of metal tiles, but insulation.

With the right location, the rafter you can significantly save on timber.

Do not forget about the features of the roof of the roof of the metal tile: this material does not flow well, as a result of which condensate often accumulates under the roof.

Secure the upper support of the rafting system to the skate run instead of the side part. This will create a small air layer, increase ventilability and help protect the roof from destructive moisture.

Slinge system for professional flooring and Ondulin

A distinctive feature of the professional flooring is lightness and rigidity, therefore, as in the case of metal tile, the requirements for the rafter system are not so high.

The distance between the rafters under the professional flooring should be in the range from 60 cm to 120 cm. The optimal cross section of the rafter foot depends on the span between the supports.

So, for a span of 3 m, the timber is selected with a size of 40 mm by 150 mm, for a span of 5 m - 50 mm in size 180 mm.

What distance is permissible between rapid legs, depends directly from the cross section of the BRUSEV: the more the rafter step, the more durable material it is necessary to use for rafters. When choosing a step more than 80 cm Increase the thickness of the bars by 20 - 25%.

Do not forget to take into account the weight of the crates under the professional flooring. The distance between the Single Roof rafters of 60 cm will require the crate with a minimum cross-section of 25 mm bars per 100 mm.

At a rapid step, equal to 80 cm, - 30 mm per 100 mm, etc. The angle of inclination of the roof plays an important role: when skate less than 15 degrees under the corrugated floor it is recommended to lay a solid crate, which is much heavier than sprawling.

Since both have a relatively low weight, the supporting structure can be quite easy, which reduces the load on the bearing walls and the foundation of the building.

The higher the degree of inclination, the greater the distance between the rafters is allowed.

On a batch roof with a slope of less than 10 degrees, it is recommended to establish a solid crate, which increases the load with roofing design.

In this case, it is better to use a thicker 40 mm in size by 50 mm, and the rafter step is minimized (60 cm).