Proper metal cutting with grinder

- Features of the work of Bulgarki.

- Distinctive characteristics of the tool

- Metal Rules

- Recommendations of specialists

- Security Rules for Metal Cutting

- Finishing actions

Bulgarian, or a corner car (UCM), is a tool used for cutting and processing any materials. It facilitates the work on the decoration of the room. Metal cutting with a grinder is an integral part of such a device. To make a cut surface, you should use special mechanisms, and it is not always easy to do this. With this construction tool, you can cut and clean the concrete, metal, wood.

For high-quality work of the Bulgarian and its long service, it is necessary to monitor its common condition and the state of its nozzles.

Features of the work of Bulgarki.

The process of sawing surfaces includes several points:

- During the work, it is necessary to monitor the degree of wear of the cutting circle. These indicators affect the depth of entry into the base of the material. Therefore, such a part requires periodic replacement.

- At high speeds of rotation of the circle, its axis is much warmed up. To increase the efficiency of work, it should periodically water this part with water. Cooling disk is the best reflected on its performance.

- Do not include the device for maximum power. So he is rapidly wear out and fails.

- The recommended frequency of revolutions is the third part of the maximum digits installed by the manufacturer.

Bulgarian can be cut and grind different materials: wood, stone, metal.

- it is not allowed to carry out a metal grinding or other material by the lateral part of the cutting sphere;

- disk curvature is not allowed;

- at the time of the movement of the circle, any items, including part of the body, should not be located;

- it is not necessary to produce unnecessary deep dives into the surface of the material, this may lead to deformation of the main part of the device and its further splitting into small parts;

- it is not recommended immediately after the acquisition of testing the cutting circle on strength, to begin, it is necessary to check the idling stroke of the Bulgarian;

- mandatory condition is the use of personal protection.

Back to the category

Distinctive characteristics of the tool

Bulgarian first appeared in Russia in the 40s of the XX century thanks to German manufacturers. Its name is associated with the further spread of this device in the Soviet era by export from Bulgaria. Such a fixture of a construction orientation, equipped with circles and disks, helps dissect metal structures, ceramics, bricks.

Choosing a model of such an apparatus, it is worth considering that high power will affect its weight, significantly weighting the device.

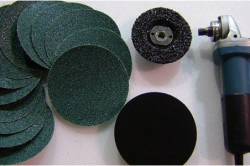

As replaceable nozzles apply:

- discs;

- brushes;

- cutting grinding circles;

- tarbed nozzles.

The details of the last type are made of plastic or rubber. They are used for thin grinding. Wire brushes are used to clean the metal from corrosion traces, and also allow to remove paint from other surfaces. Cut circles with a thickness of 2-3 mm can be flint or corundum. Diamond options are suitable for grinding stone or tiles.

Any Bulgarian is equipped with discs, the diameter of which corresponds to 230 mm, 150 mm, 125 mm, 115 mm. Circles of small size are very convenient to use. Regardless of the dimensions of the disks, it is necessary to use a protective coating in the form of a housing. When the device is turned on, it should be retained with both hands.

Back to the category

Metal Rules

Metal cutting with a grinder is associated with the installation on the device of special disks. The protective casing is regulated in this way as to protect the eyes from the random hit of the smallest particles. To ensure high quality cutting of metal objects, the tool is slightly moved to themselves. So sparks will fly into opposite to the person. Dropping movements should be carried out perpendicularly, without unnecessary presses on the body.

Cutting metal requires particularly accurate treatment with this raw material. Here you need to take care of your own security. The main cause of injury can be the departure of fragments at the time of work. These include particles of cut material, sparks, dentive debris wreckage. For this reason, it is necessary to wear safety glasses before working. Hands are protected by gloves. To avoid breakdown saw, it is necessary before turning on the device to determine the trajectory of movement of the cutting mechanism.

Back to the category

Grinding nozzles for the grinder have different degrees of roughness from large to the small one.

It is known that any metal, including pipes, can be cut. Sleep them best on the side of hanging edges. The processing of iron products in the middle part often leads to a deflection and jamming of the disks. When working with the metal, the accompanying efforts are sent to the lower part of the work disk, which is responsible for the effectiveness of the propyl. Every 20 minutes of operation, the saw should cool, for this, interruptions should be taken. This is especially true of devices with small power, which overheat very quickly.

Starting to the cutting of aluminum, it should be understood that certain difficulties may appear due to the viscosity of this metal.

Sheet or dense item requires a seam processing kerosene.

However, in the process of work, it is necessary to ensure that ignition does not occur.

The pretty wear discs should not be left immediately, they can come in handy for cutting tin elements, moldings. Cutting the corners is distinguished by an uniqueness: to process them in 2 receptions, one strip is cut first, and then another. No need to put it on the grinding knob, its slow rotation speaks of the need to replace the disk.

All items should be removed before carrying out work: all items are removed from the device: hot metal elements when hitting any surface lead to their adhesion. It will be almost impossible to get rid of this.