Roofing from metal tileage

Metal tile is popular in the private sector. This is due to the durability of the material, beautiful appearance and good protective properties. It is also important that it is easy to stack on its own without resorting to the help of specialists. Laying Metal tile includes: the choice of material, calculation, the preparation of the roof and the actual work on the installation of the coating.

How to choose metal tile

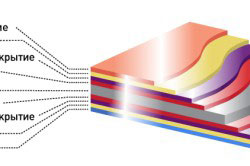

Modern metal tile in appearance is similar to natural tile. But it is an order of magnitude better protects the roof from bad weather, has more variations in color and not so road. The thickness of the sheet metal tiles is 0.5 mm, it is covered with a polymer. For this, polyester, Pural, Armacor, Plastisol are usually chosen.

What an external coating to give preference, largely depends on the climate where the house is located. It is necessary to do not only in appearance, but also based on weather conditions and temperature drops that will be throughout the year.

Polyester is perfect for any climate. Metal tile with such coating withstands large temperature differences. The minus is the fragility of the material, so caution should be taken when laying. Purally does not fade under the influence of sunlight. This coating is stronger than polyester, although it is thinner.

The coating is similar to Puralo - Armacor. He opposes the direct sunlight, does not fade. Armacor is not afraid of any, even the most severe climate. Plaserisol also opposes mechanical damage well, but when heated above + 60 ° C is in disrepair. In addition, it is not as other coatings, resistant to sunlight - paint will quickly burn out.

Material calculation instructions

Before laying the selected metal tile, it is necessary to calculate how much material is necessary for this roof. The complexity at this stage lies in the fact that the rollerpiece is asymmetrical. That is, in the installation process, it is impossible to confuse the top and bottom of the coating. Therefore, if the roof of a complex design, has many protrusions and elements, will become difficult.

Stages of calculating the amount of material:

- We transfer the roof plan to millimeter paper, given all sizes. We measure the length and width of the skates.

- Any metal tile has two lengths - general and useful, since the material will fit the flashes. Usually the useful length of all manufacturers coincides. It is 111 cm.

- Calculate the number of vertical sheets of metal cells. For this, the length of the skate horizontally divide on the working width of the coating. The resulting number is round to the whole side.

- We determine the length of the tiles sheets in a row by the formula:

where A is the number of sheets, X - the length of the roof of the roof from the skate to the eaves, y - allowances for the eaves (standard 5 cm), z - allowances for the overwest sheets in the vertical direction (15-25 cm). But if the length of the sheets allows you to spend in one row, then the overheet is not taken into account.

- Calculate the number of challenges on the construction structures of the roof (skates, planks). For this, the length of the construction structure is divided into the working length of the challenge (usually 190 cm). The resulting number is round to the whole, in the most side.

- Calculate the number of screws for fastening. For the roof: the roof area is multiplied by 8. For the Dobly Elements: The length of the planks multiply on 8. We fold the numbers. This is the necessary number of self-tapping screws.

Technology transportation metal tile

To independently install the metal tile passed correctly, you need to pay attention to the delivery and method of storing the material.

- Metal tile should be loaded using soft sling. Sheets should not stick out from the body of the machine so that they do not break. It is forbidden to lay other materials (the more severe) from above.

- Packaging with metal tile must be transferred in a vertical position, without provisions and breaks.

- Sheets can not be stored on bare earth. It is best to fold the metalochief in the dry room. If there is no such, then under a canopy on the flooring from the tree.

Preparation of roof

Instructions for work

The installation rules of the metal tile are as follows: the work should be started from the bottom bottom corner of the roof, it is impossible to walk in the shoes on the rigid sole, and you can only step on the metal tile where the material comes into contact with the crate.

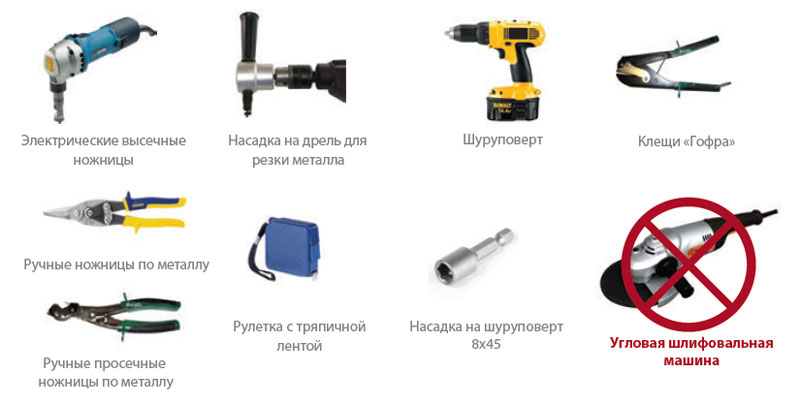

Tools for laying and fixing: scissors for metal or hacksaw (in order to cut sheets), rechargeable screwdriver, hammer, screws, ropes, staircase, boards and rails to raise sheets on the roof.

Molding rules Metal tiles are as follows:

- Before starting work, you need to get acquainted again with the instructions.

- The laying of the material goes to the left of the right, brass.

- To the lowest board, the shell sheet is laid over the step, to the rest - as close as possible to the bottom step.

- After the sheets are laid, they need their hands tightly press to the roof boards.

- Metal tile is attached to the roof using self-tapping screws. Fastenings should be with sealing washers. Sheets are fixed between the waves. Self-tapping screw should be included in the corner of 90 °.

- Special attention should be paid to the installation of material on the skate. For one must be sure to leave space under metal tile. Therefore, on the skate sheets are fixed with gaps. At the top of the sheet, it should be inspired, and the horse is fixed on the tapping screw.

- Near the walls of the building sheets of metal supplies are also insulated. For better pricing to the house you can use special planks.

- At the end, it is necessary to install a horse and ground the roof.

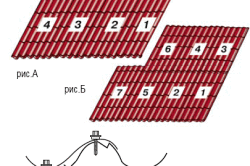

Metal tile stacked in one row:

- put the first sheet from the bottom edge of the roof;

- align on the eaves;

- "Help" a sheet in the center for a self-tapping screw;

- even first, lay out the second sheet;

- fastening technology of sheets - mustache;

- using this method, mount 4-5 sheets in a row except the latter;

- consolidate all sheets with self-drawers (technology is described above);

- share the next row, only after that fasten the last sheet in the bottom row.

Metal tiles fit into several rows:

- instructions for fastening the first sheet is similar to the previous one;

- the second sheet is not near (left), but from above;

- "Help" metal tile;

- check, even whether they lie, fasten them with self-draws to each other;

- the third sheet to put on the left of the first, and the fourth over the third, etc.

Sheet laying technology on triangular rods:

- determine the center of the skate, mark the line;

- on the sheet metal tile also find the center and spend the line;

- installation should be started from the skate;

- combine the marks on the roof and sheet;

- metal tile fasten;

- the instruction for the subsequent attachment is described above.

Proper trimming sheets of metal tile

It is best to select sheets so that they do not have to cut them. But if it is impossible, you need to use an electric jigsaw or saw for metal. It is strictly forbidden to cut metal tile with cutting machine. Sheet sections need to be treated with bitumen mastic to prevent corrosion.