Stages of mounting roofs from metal tile

The roof of each house is very important from all points of view the element. It performs one of the most important features of any room (regardless of it is intended for housing or for any business) - protective. It is on the roof from all sides that the real squall of all sorts of incathions is constantly collapsed, which leads physical and other types of damage to the roof. Thus, the roof, speaking by the defender of your home, takes the whole blow to herself. In order to at least reduce the level of this voltage and negative impact, it is necessary, firstly, to properly make the choice of building materials, secondly, professionally carry out the laying of selected roofing materials and, of course, constantly monitor their condition. It is these 3 important steps that will lead you to what you do not have to get a few years after the end of the roof is completed to its overhaul.

The roof performs one of the main functions - protective. Provides your home comfort, cleanliness and comfort.

Rules for mounting the roof of metal tile

If you intend to apply roof on your own home, the best option will be such a material like a metal tile. It is used in this sphere for a long time, has its own characteristics, however, so far many nuances are still set to install this type of material on the roof, not everyone is known.

Main characteristic of metal tileage

More recently, the metal tile as a roofing material was almost alienated here in Russia. For the most part, it was an imported material imported into the country under the "Rannila Steel Oy" brand. Now the number of manufacturers has significantly increased that, naturally, it affected the products offered in construction stores. And at the price, it also affected, because the value of metal tile of domestic production is much lower than those established on products of imported deliveries. The choice is metal tiles will become a wonderful alternative to the real tile. After all, not everyone, forces and forces, buy natural material, and metal tile is a kind of "budgetary" option for those who cannot afford more expensive roofing materials.

The minuses of this choice include the fact that in cold climatic zones, he is very badly kept warm in the house.

By the cons of this choice include the fact that in cold climatic zones, he is very badly holding heat in the house and, on the contrary, it skips cold air flows from the outside. Accordingly, there will be no noise insulation in this case. That is why in order for your decision to subsequently disappoint you, you will have to use additional materials and conduct relevant activities to increase the indicators of sound and thermal insulation. The appearance of the metal tile will immediately transform all your facilities and now besides the protective function, the roof will perform aesthetic, decorating the house and giving it a complete view. Saturated and bright colors will allow emphasize exactly on your facilitation. It is not only able to resist the sunshine and, accordingly, does not fade, but also always looks almost like new. In addition to the above, the metal tile is a lightweight variant of natural material (tiles), which makes it easier for the process of applying a roof to this or that building.

Metal tile has several varieties. The most similar to natural tile is such her appearance, like Monterrey, he, accordingly, the most expensive. The option is presented as well. It allows you to save on the fact that it has an unusual form and, accordingly, a larger size of individual sheets. Externally, the cascade is similar to chocolate tiles. And the third option is called Shanghai. It is more suitable for the roof of large buildings. The kind of it resembles a certain mixture of two above-mentioned varieties, although the height of the crest in it is much higher. So, given the fact that all manufacturers that are now on the building materials market offer each of the three types of metal tiles, we can say that it has really expanded it over the past few years.

In the process of production of sheets, metal tiles is used fully automated complex.

In the process of production of sheets, metal tiles is used fully automated complex, in other words, a human factor that may adversely affect the quality acquired by material, completely excluded. Many believe that this material is too thin and therefore poorly protects the house from possible chemical and physical damage. But this is absolutely incorrect, as the metal tile, despite its absolutely inexpressive and insignificant thickness (the source sheet is not thicker than 0.7 mm), strong enough. In the same place, in production, the metal sheet is treated with a polymer material, which allows you to extend the service life of the roof from metal tile.

Sequence and basic rules of installation of metal tile

The main condition for covering the roof by metal tile sheets is the inclination of the roof of at least 10 degrees.

As already mentioned, the metal tile is not very good isolates the cold and noise, so it is necessary to create the so-called "puff pie" from sound insulation and insulation materials. Especially for this, the Council should heed with those who decided to build right under the roof of the attic or a real residential floor. Few who will like to sleep in a rainy night, but to count the drops falling on the roof. That is why it is necessary to carry out all the metal tiles prescribed by the manufacturers on its laying. The main advice, which gives professionals of software is that the bias of the roof with such a flooring should not be less than 10 degrees. If the angle is more than 20 degrees, you need additional work on sealing joints. Taste with a longitudinal coating should not be less than 25 cm, with a transverse one for a whole corrugation.

For this purpose, it is not allowed to use abrasive circles, which one or another metal is usually crucified on the grinder.

If the length of the roof slope exceeds 6 m, it will be necessary to calculate the necessary dimensions of the acquired material with the condition of addition on the necessary joints.

In this situation on the place where it takes place, the temperature is very quickly rising. As a result, the protective stained polymer layer is burning apart and, sometimes even the metal itself. All this leads to the further destruction of the composition of the material and the easiest of corrosion, which will be further connected with others, even with the most insignificant effects. With the usual pickle, do not forget that constantly formed sawdust must be knocked from the sheet so that it does not damage. In the event that the length of the roof slope exceeds 6 m, you will need to calculate the necessary dimensions of the acquired material with the condition of addition on the necessary joints. This will allow you to save forces on the installation, as working with short sheets of metal tiles is much more convenient than large-sized. In addition, this process is quite dangerous on the roof.

Rules of laying metal tileage

In order to exercise you will need:

- metal tile sheets;

- electric jigsaw;

- screwdriver;

- self-tapping screw;

- building level;

- wooden timber and boards;

- nails;

- waterproofing;

- stapler.

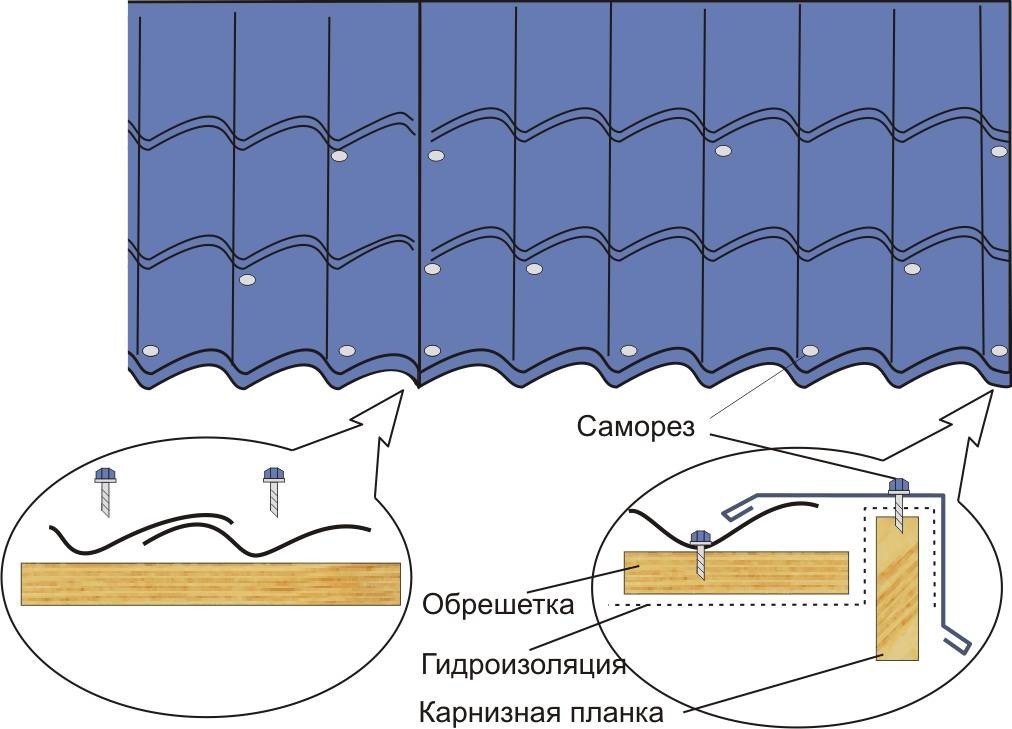

As with any other roofing material, under the metal tile you will need to word. These rules are most often the same. Unlike the coating of natural tiles there should be no reinforced coating, but there are some rules for which these activities are conducted. First, a doom is needed. To this end, you will fit a wooden bar and boards. The step between the bars should not be more than 70 cm. If this happens, then you will need to apply a fairly dense layer of boards. If the bars you have strengthened within the allowable norm, then the boards can also be arranged a little less. The height of the boards stuffed with a broken crate should not exceed the size of 5 cm.

After all this design is fixed, you can go to. This is done using conventional sheets that are sold at any construction store. The range of such films is very wide and you can choose them at your own discretion. For their attachment, a stapler with large brackets is used. Waterproofing should not be located on the roof in the stretched state. The clearance length should be at least 1.2 - 2 cm. Such a procedure can be repeated several times and make multilayer insulation. In some cases, experts use different types of films for waterproofing. They depend on what type of roof you cover, on what natural conditions the house is being built.

Features and sequence of styling metal tile

Already after that, we proceed to the mounting of the metal itself. It begins its laying from the lower edge of the rectangular skate. The most convenient way is such in which the laying scheme of the metal tile starts from the lower lower angle of one slope. The first sheet of metal tile is attached to the bottom rake. Specialists advise first to take a temporary mount with a self-tapping screw with the help of an ordinary screwdriver. This method is needed to ensure that in the event of incurdictions with subsequent sheets, you could adjust the first sheet. Its evenness must be carefully reconciled using a construction level. Next occurs the alternate imposition of the next sheets of metal tiles to each other. Move is necessary from the lower edge of the skate to the skate. After performing work on one row, you can go to the neighbor. Some some use another way. First strengthen the top row in the skate, and then in turn lay down each subsequent sheet under the previous one. This execution is not recommended, since the constant effect on the already fixed part can damage the surface of the sheet.

Self-screws are twisted in places below the stamping line by 1.5 cm in the middle between the ridges of adjacent waves in a regular place, where guaranteed, there is a board of a step crate.

Starting from laying the lower row, prefer the longest sheets. This will significantly facilitate the load on the entire roof. Also, do not forget that a large amount of water will be able to drain from the roof as a result of precipitation. Therefore, do not leave open cornice. The minimum value of the roof of the roof over the cornese should be 40 mm. Connecting several sheets, we draw attention not only to the coincidence of their edges, but also on the features of the waves of the combined parts. Molding of metal tires is made using self-tapping screws.

The distance between them should be no more than 35 cm. They are screwed and the screwdriver and, if there is no possibility to purchase it existing in almost every drill. It should reduce the amount of its revolutions. Self-tapping screws can be attached at the bottom of the ridge, as well as on the upper part of it. But at the same time, do not forget that the dimensions of self-samples in different cases should be different. Some builders are not advised to screw the screws into the upper crest of the wave, but if you are still going to do this, then you need to build places in bars or boards in advance, to which the metal tile sheet will learn. In the first (in the lower), the sheets located near the eaves, the self-tapping screws are screwed into every wave. Further (in the second and third sheets), you can fix them through one wave. It is possible to cut the material not only by the electrolovka, but also by the usual manual or cutting electronics. Circular saw is also suitable for these purposes.

After all the installation works are completed, you should not count that this is completed by your work. From the roof neatly sweep the whole enhancing chips, in places where scratches are formed, it is necessary to conduct decorative repairs. Once every 2 years, do not forget to wash the roof of a weak soap solution. After several months after covering the roof, it is necessary to spend a tightening of the screws, because the material will take place and you will need to strengthen the roof.