Raw metal of metal tile

The duct roof is a fairly simple roof design, its calculation and construction can be performed on their own, without the involvement of specialists. The functional parameters of the roof depend on the characteristics of the insulation, the bearing capacity of the rafter system and high-quality installation of metal tiles.

For the correct calculation, it is necessary to carefully read the stages of the works presented below:

- preparation and design (in this stage include the calculation of everything necessary in the future);

- arrangement of the rafter system, taking into account the type of building and the necessary requirements for the attic room;

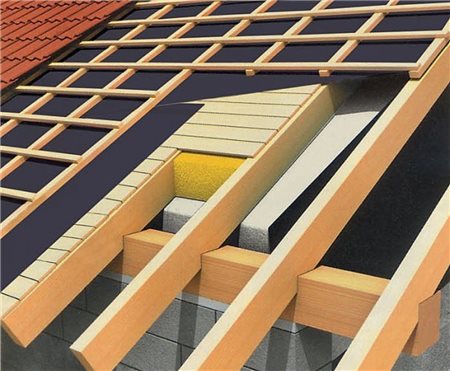

- laying the layers of heat, paro-,;

- the arrangement of the crates;

- installation work of the selected roofing material;

- arrangement and.

Immediately before the construction of the bartal roof, a complex of preparatory work should be carried out, including:

- designing the roof with two slopes;

- preparation of the necessary building material, and material for the rafter system, and insulation, and a film for waterproofing, a vapor barrier film, fasteners are included. Preparation of the necessary tool for work;

- preparation of bearing walls for roof arrangement.

The preparatory stage is quite important for the qualitative implementation of the entire complex of work. Quite often, all work depends on the correct calculation and selection of the material.

Not only sustainability and durability, but also the appearance of the entire building depends on the embodiment of the rafter system. Start working with a rafter system with styling of timber-mauelalat, which allows you to protect the bearing walls from atmospheric precipitation. The beams are laid on this bar, which serve as the basis for overlapping racks.

Fasteners are performed using large nails or screws. The arrangement of the attic room is necessarily planning in advance, as it requires some changes in the design of the rafter system.

Next, the installation of the frontones, which are the continuation of the plane of the walls. Fix the rafters directly to the front alone, making the so-called "sank". The tops of the frontones must be on the same level. Fix all the elements of the system using special metal corners with holes for fasteners.

At this stage of work, the roof is insulated and insulation. For this, materials are used as:

- waterproofing film;

- various breathing diffusion membranes;

- mineral wool or polystyrene slab.

From above, rafted with a stapler fasten the waterproofing film. In the future, it will also hold the slats of the crates that are stuffed along the rafted. Be sure to leave a small sagging of the film, about 2 cm on the span between the rafters.

In the interval between the rafters, it is usually the distance of about 80 cm, laid a layer of insulation, leaving the gap between the surface of the insulation and the waterproofing film. The lower part of the insulation is covered with a vapor barrier film. Be sure to perform the following conditions:

- all materials and films used must be without defects, cracks and cuts;

- all films are also stacked by peaks, the joints are sampled by scotch;

- the insulation must fit tightly to the surface of the rafted, without gaps;

- all materials are selected for a specific coating, under the installation of metal tiles go alone, under the soft roof - others.

During the construction of economic buildings, the layer and vaporizolation is usually not used to reduce costs.

Installation of crates start with fixtures along rafters. These planks, as already written above, additionally hold waterproofing. Perpendicular to these plars are picked up a counterclaim. Metal tile will be performed on these planks.

The counterclaim is performed at a distance between the planks of about 35-45 cm, which allows you to securely secure the metal tile in the future. Fix the wind and skate planks. If necessary, fix brackets for the drain system.

Work on laying metal tile on a bartal roof is usually starting from the bottom of the lower edge, if you look at the front of the building. To begin with, it is necessary to put several sheets of the brass and align their lower parts relative to each other and relative to the eaves.

To facilitate the leveling process, you can fix a pair of screws to different parts of the eaves and pull the color fishing line or thread between them, alone it relative to the cornice.

Now all sheets will need to be located on the surface of the bartal roof, aligning their lower parts along the stretched thread. If you need to trim the end sheets, it is necessary to use special electrical scissors or an electrolovka.

It is not necessary to use the Bulgarian, especially when there is nothing to handle the cropped edges to prevent corrosion development.

Fasteners for metal tiles should be purchased with sheets, picking up the self-tapping screws. Each self-tapping screw should have a rubber washer that impedes the penetration of moisture inside. It follows in a soft shoe, which will prevent damage to the protective layer of sheets.

After laying, the metal tile on the bartal roof must be grounded, since the metal easily performs electric current and can become a vulnerable place when the lightning strikes.

Various sensitive electrical appliances may suffer from this. No complex designs apply no need for a fairly regular pin or antenna structure.

The bartal roof of metal tile is pretty simply simple, especially if there are several helpers, which will be simply necessary when working with a rafter system and when laying tiles sheets.

After completing all the steps of work, you can get a beautiful, reliable and most importantly safe roof for your home, which will delight your fortune for many years.