We make roof yourself

Outows often use two completely different words - roofing and roof - in the same meaning. In fact, it is impossible to do this. And any experienced builder will explain to everyone that under the roof in this area implies everything that is located in the room, that is, above the residential space, which is usually called the attic. But under the roof, the upper part of the building is understood, that is, the roof cover directly, which is irrigated by all sorts of precipitation, closes the inside of the house from shrill winds and hot sunlight.

The roof of the house protects against external natural factors, such as: rain, wind, snow, so it is worth thinking about a strong and high-quality roof of your home.

However, you need to remember that before thinking about creating a roof, you need to pre-arrange a roof. That is why, first of all, it is necessary to know the rules of how their hands of a residential building or non-residential, but no less strongly needed in the coating, premises. Although it sounds proudly - I made a roof with my own hands, but anyone able to think abstractly, it will understand that it will not only be difficult to cope with such a difficult task that it is most likely impossible.

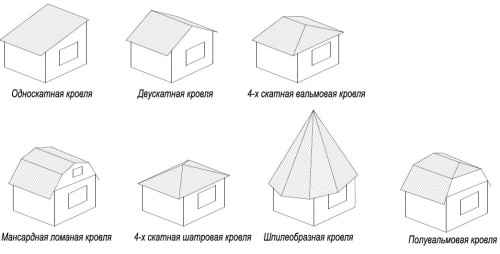

Main types of roofs

Varieties of the shapes of the roofs. The most common single-sided and duplex roofs.

Specialists call only 2 types of roofs, which are considered basic in construction. These are flat and scanty. And from the point of view of materials used in this case, and from the point of view of the technology of the construction, they differ from each other.

In order to make the roof of any type, the following tools and materials will be required:

- nails;

- bars;

- board for the crate;

- ruberoid;

- hacksaw;

- a hammer;

- chokline;

- roofing material.

How is the plane roof?

Flat roofs that we see are mainly in industrial factories, factories, and, of course, in residential buildings, you can also build with your own hands.

The main material from which can be made of a flat roof, concrete slabs are considered, and to build a similar roof at a high-altitude house, no matter how cool, do not work out.

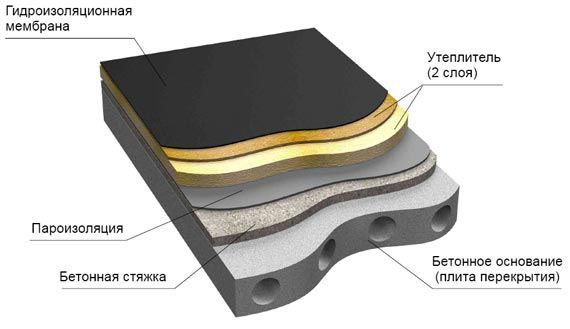

Flat roof structure.

If, of course, you are not Hercules or Titan, which is able to keep the heavenly arch and you can compete by the heavy construction equipment. But if you need to make a roof for some kind of home building type of cellar or garage, then the independent erection of a flat roof will be for almost any man. Provided that the roof will be collected from small elements or will be a monolith of reinforced concrete.

A set of flat roof is made as follows: On the walls of the building covered are stacked beams that can be made of metal or wood. They will serve as supporting, which will later fall the main load of the roof. At this stage, you need to pay considerable attention to which thickness will be installed beams. After all, they have to keep not only the weight of the roofing material, but also the weight of snow, which in the context of the Russian winter is absolutely inevitable. Plus, by the weight of at least one person who will have to clean this snow. Since he does not melt for a long time, the flat roof does not imply independent snow rolling.

Flat Roof on Unheated Rooms

Unheated construction, such as a barn, garage, gazebo, terrace or canopy assumes a flat roof slope over the entire area of \u200b\u200bthe room. For this, carrier beams are immediately installed with a slope. Then the wooden shield is placed on them, which is obtained by solid laying of boards, on top of which rubberoids, which need to be laid tight towards each other, so the original carpet. The higher the quality of the density of the lining of the roof of the rubberoid, the lower the likelihood of its flow.

Rubberoid is recommended using rails that, in any case, can be replaced with metal stripes. They are nourished at a distance of 60-70 cm from each other along the slope, and it will not prevent the flow of water. The bias we leave at least 3%. This means that each m length of the roof is made at least 3 cm elevation.

Flat roof on residential premises

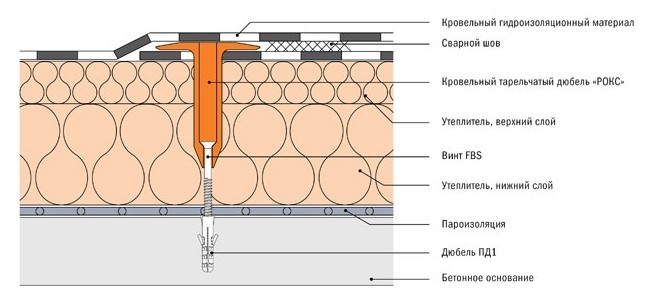

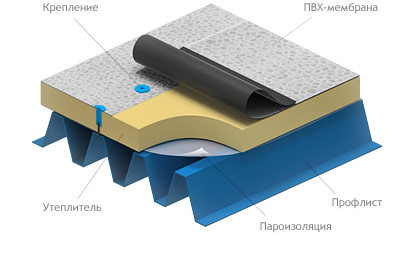

Fastening roofing material to a flat roof.

A flat roof with your own hands can be done for heated buildings. In this case, it is necessary to act as follows: the laid beams are covered with wooden boards and already on top of it 1 layer of roofing or rubberoid is stacked. Fasting bands need to be made at least 15 cm, the insulation is poured over this layer, it is usually a slag or clay. With the help of the insulation, a slope is formed to the other side where rainwater will die and snow dropping. According to the insulation, we perform a tie of the cement mortar, the thickness of which should be at least 2, see. We are waiting for the moment when the screed is completely dry, and processed its bitumen primer to which a rolled rover is pasted from the runnerdoor.

Concrete monolithic flat roof

When the roof is made of monolithic concrete in the form of supporting beams, 2-way steel beams are used.

For a successful flat roof device from a monolithic concrete, it is necessary to use metal 2-way beams as bearing structures. Considering the roof device, the span of which is 4-5 m, experts recommend using beams, the height of which is approximately equal to 12-15 cm. In the language of professionals it sounds like a "fifteenth dvoavr". Concrete used to create monolithic overlap, it is better to buy ready, because Purvating mixing of concrete without using concrete mixer will not allow you to achieve a uniform connection of all components components. Concrete will be heterogeneous, which will adversely affect the quality of the coating. To prepare concrete with your own hands you need:

- 3 buckets of cement;

- 4 sand buckets;

- 8 buckets of rubble.

All this is mixed using 2 buckets of water. Sometimes water is required slightly more, so its number can be adjusted independently.

Next, the boards are laid on the lower shelves of the beams, on top of which dry needed 1 layer of rubberoid or roofing. Then it is placed in such a way that it is formed by the semblance of a grid with cells, the approximate size of which should be 2x2 cm. In order for the grid during the installation of concrete, the rods are needed, the rods in the places of intersection need to be either welded with electrical welding Wire, the diameter of which does not exceed 2 mm. It is also necessary to provide a small space between the grid and the runneroid no less than 4 mm so that the fittings completely closed concrete. To achieve this goal under the grid it is necessary to put small pieces of crushed stone. The cooked concrete is placed between beams with a minimum layer of 15 cm.

In the process of laying the monolith to the roof of the building, consider the fact that the strips between the beams need to be filled in turn. Since this work is likely to be delayed not for one day, and to achieve the highest possible screed, it is impossible to share the concreting of one strip into several approaches. During this work, it is necessary to carefully seal the concrete with the help of a vibrator, and if you do not have it, you can use the hand-made traam. At the same time, it is necessary to really try not to shift and not damage the reinforcement grid laid for a concrete screed.

After the concrete is laid, builders are recommended to close it with a plastic film, in order to avoid too fast evaporation of moisture from concrete. It is especially important to do it in hot summer weather. If this is not done, the top layer of the roof will soon crack. To withstand the concrete mixture under the film you need at least 3 days, after which the film can be removed.

After complete drying of the concrete, it is possible to proceed to the device of the slope, which is constructed using a heater, a cement screed device and, in the end, a sticker of a rolled carpet. These stages are described above.

From a detailed description of how to make a flat roof with your own hands, it can be seen that there are no special technological difficulties here. It is much more complicated about the affected roof, which requires a high accuracy of measurements in the manufacture of bearing structures, and then the roof directly. It is already unlikely to please it, because the angle of inclination The pitched roof has a greater than flat.

Scope roof and her creation with their own hands

Scope roofs prefer to build on low-rise buildings - private single, two- and three-storey domains, as well as cottages, small cottages and, of course, five-story "Khrushchevki". Often, pitched roofs complete unique buildings.

Scope roof, which matures not a very massive structure, for example, a garden house, a bath or a gazebo, you can make with your own hands even on the condition that only 1 person will perform work. And if you decorate the rope roof on a pretty overall building, then one is unlikely to manage, you have to call two or three helpers.

How to make a scope roof?

As the basis of the pitched roof take rafters, with which quite complex structures are formed. In professional construction, this type of structures is called the famous all-word "farm". As a rule, rafters are based on the walls directly, but experts recommend installing Maurylalat. In other words, the bar, which is placed on the wall and fixes on it using anchors. And the rafters rests precisely to these bars, which are attached to metal brackets or other methods that ensure reliable connection of the supporting structures.

Stages of creating a scope roof assume the following sequence of actions:

- install Mauerlat;

- strengthen rafters;

- construct and install the ski bar;

- make the crate.

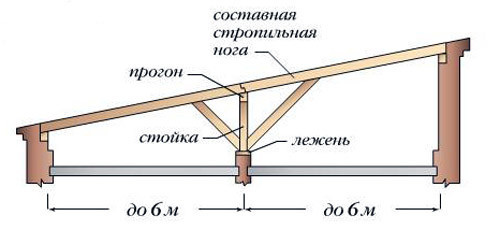

The lines of a single-sided roof system for two spans 6 meters.

According to the created crate, we are placed directly. During the construction of the roof of this type of rafters, they try to release the edges of the walls, in order to build the walls of the construction created with the wall of the construction from entering it moisture, for example, during the rain or when the snow melting. The best option is the elongation of the rafted themselves, for which you need to navigate the board with a thickness of 2-3 cm. In the future, this board can be used as a basis to which the windscrews will be felt.

The rafters, as a rule, are collected directly on the roof, raising the prepared elements in advance and collect them on the approved scheme directly on the roof. There is another option to make the finished rafter farm, which consists of 2 rafting legs, racks and, of course, tightening, right on Earth. After that, the collected design, which has pretty bulky sizes, raise vertically exactly to the place where it should stand. This procedure does not work with your own hands, no matter how hard you try, so you have to use the help of heavy machinery. After installing the farm to the top of the house under construction, fasten it to Mauerlat.

At the end of the installation of existing rafter structures, it is possible to combine them with the help of a skate bar, and then do the crate.

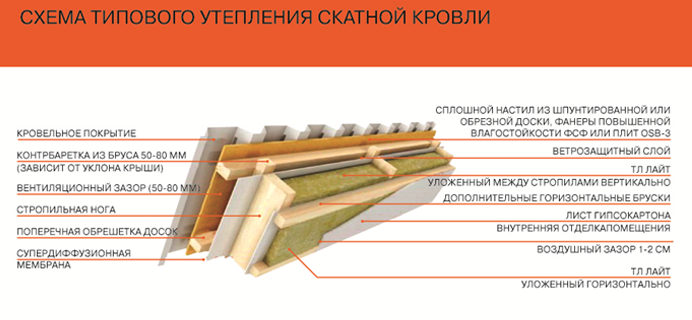

Creating a roof trim under the roof

Construction of the frame of any roof is carried out in two stages: installation of the rafter design and the execution of the roof shawl.

It is easiest to make the crate from the boards that nourish "in the disintegration", that is, after a certain distance between them, or the "skip" when the boards nourish back to each other. In order for this stage to be too expensive, it is possible to use a cutting sawn timber with a thickness of only 25 mm. Before strengthening the boards on the roof, they need to carefully clean from the remains of the bark. To nail the crate to the rafters use nails in 70 mm. The boards, as a rule, are not perfectly even, so in the case of a solid crate device, they will need to be customized in place with an ax to reduce the gaps between them.

The design of those elements that are used for the crate, and their dimensions depend on which roofing materials you plan to use in operation. If your roof is closed with metal tile, then the unedged board is undesirable to use. It is better to replace it with a timber that needs to be knitted "into the dispersion", at a distance equal to the wave of the roofing material used.

Those who use ondulin or various kinds of bituminous tiles are made as follows: drives from a bar are nailed to the rafters, the size of which is 40x50 mm, at a distance of about 50 cm. On the resulting runs with the help of self-soles, OSP sheets are strengthened. This solution will be successful for those who plan, for example, to create a living room instead of the attic. Such a solution is called the attic roof, due to which it turns out to be successfully enlarged at the living area of \u200b\u200bthe house.