Safe work Bulgarian

The corner car, it is Bulgarian, is a very attendant tool. Do not be so irreplaceable with many types of work, it would be possible to impose a restriction on the use of this tool. In disassembled, scattered and "crook", the work of the grinder is categorically contraindicated. In general, it is very important to know how to work with a grinder.

Getting started

Becoming for work with the grinder, you need to be extremely collected. You can not take a tool, being tired, unhealthy, and even more so drunk. Fatigue creates carelessness, which can do expensive when working with a grinder.Protective casing and glasses - Mandatory conditions for safe operation. The two most important rules that must be carried out strictly - can not work with a grinder with a removable cover and without glasses. Sparks, abrasive particles, metal fragments and scale - inevitable satellites when working with a corner car. Entering them in the eye can lead to injury.

Points or replaceing their mask must be closed. Sparks and fragments fly through a complex trajectory and are able to fly for glasses or a mask if they are open from the outside. It is not bad if the mask will have a safety grid, since the blows of the circle fragments can be so strong that the unmarked mask may not withstand the blow.

The protective casing is the first barrier standing between the operator and rotating with a huge speed circle. The destruction of the latter is quite frequent phenomenon. Many who more or less regularly use the grinder, at least once, but come across him. Most often, the destruction of the circle occurs when clamping it in the slot.

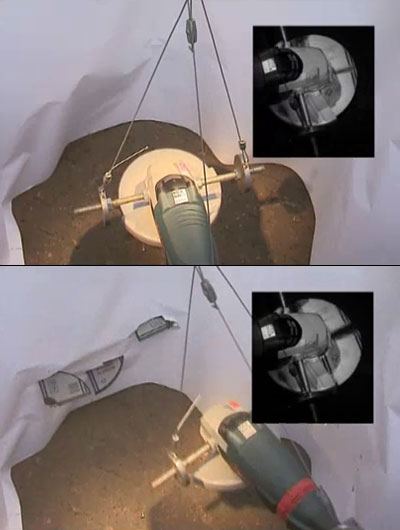

The protective casing is set in such a way as to exclude the emission of sparks and fragments towards the operator. Below are images that clearly show how the casing protects the operator in the event that the circle collapsed during the rotation. It is clearly seen that the separation sector of fragments is set by opening in the casing.

At the end of the article there is a video of this experiment.

The fastening of the casing should exclude its spontaneous flap. It would not be uncomfortable in some cases to work with a casing, its removal from the tool is unacceptable. Otherwise, the operator is not insured against the most unpleasant consequences.

Other personal protective equipment. In addition to the glasses to the obligatory means of individual protection during the work of the Bulgarian, there are also mittens or gloves. Hands are in the immediate vicinity of the rotating circle and must be protected from sparks, abrasive particles and metal fragments. It is best to protect hands to use dense leather gloves, cotton can not serve as a reliable protection against sparks.

The antique respirator or mask is used if the stone materials are processed without using dust suction devices.

Clothes should be not wide and well refilled. Catching parts can be tightened with a rotating circle.

Removable tool

For each type of work (view of the material being processed), its abrasive tool is intended. You cannot use circles that are not intended for this type of surgery.It is unacceptable to install the larger circles on the grinder than those for which it is intended. Corner-glasses of small sizes have higher speeds of rotation than the machines of large sizes. Circles of large diameters (both new and ex-in operation and decreasing in diameter) may not withstand high speeds and collapsed. This is all the more dangerous that for the installation of a large circle, you have to remove the protective casing. In addition, too high load from the rotation of a large circle causes elevated bearing wear and reduces the tool service time.

![]()

You can also use damaged circles: with cracks, chips and potholes that have deviations from roundness or flatness. This can lead to the opposite strike and the final destruction of the circle with creating a traumaous situation.

One of the most important safety requirements for the work of the Bulgarian is the inadmissibility of the use of sawing circles for wood. By virtue of its emergency danger, this should be absolutely excluded. The history of the operation of Bulgarians is full of tragic facts that appeared the result of installing saws on them for wood.

This is due to the fact that the tree is an inhomogeneous material in which there are bouts capable of bringing to the opposite strike. Can get caught and nails. In addition, the Bulgarian has very large revs, and the saw blade will quickly fill.

After installing the tool, it is necessary to check the operation of the grinder at idle for at least 1 minute at maximum turns. At the same time, the circle should rotate freely, not rebel protective casing, and the vibration should not be more common.

Fastening the processed details

If its own weight of the processed part does not provide its guaranteed immobility during operation, the part must be securely secured in the vice or clamps on the heavy design. It is impossible to work while holding the workpiece in the hands. This violates the two security requirements at once - Bulgarian is held with just one hand instead of two, and the blank is not ensured. With such a work, the displacement of the workpiece relative to the circle is inevitable, which means that the risk of stiring the latter with the reverse impact.When laying the workpiece, its bending must be excluded in the cut zone, especially if it narrows propyl. In this case, it is almost inevitably the root of a circle in a cut and reverse blow. Properly laid billet should have stops in the zone of propil and at the edges.

Work

When working with a corner car, a number of general requirements must be performed.Bulgarian should be firmly held in two hands. This is a fundamental requirement that must be carried out strictly. If the tool hold is quite reliable, then even the reverse strike will not lead to a large displacement of the tool or pull it out of the hands.

It is necessary that the position of the body is stable, without the possibility of a malfunction.

The power cord should be located away from the rotating circle. Otherwise, it can be cut or captured a disk. Both will create a dangerous situation - a short circuit and a sharp stop of the disk with a tool displacement.

It is impossible to produce a coal-lifting machine from the hands until the rotation of the circle does not stop completely - to avoid engaging the rotating circle of any objects or the supporting surface.

When you go from one desktop to another, you must turn off the tool. The rotating circle can capture clothes or hurt foreign items.

If when working it happened in the power supply, it is necessary to turn off the grinder so that when the power supply is renewed, its uncontrollable launch occurred.

When working, cutting and grinding circles are very hot, it is impossible to touch them until they are cool.

All unauthorized persons should be at a safe distance from the working area - so that the flying sparks and abrasive particles are, and in the event of an accident and fragments of the circle - they could not harm them.

Cutting Bulgarian. You need to enter the circle to contact with the material with the full spindle speed, otherwise there may be a circle.

Perhaps this is precisely this security requirement is violated by users most often. The fact is that with such a testing of the tool, the sparks flying out from under the circle hides the markup, which deprives the ability to drive a circle on the intended line. Therefore, many users deliberately violate the security requirements, leading in the direction opposite to the rotation of the circle. In this case, the sparks do not hide markup, and it is more convenient to lead the accurate cutting. And, nevertheless, the proper exploitation of the Bulgarian implies the instrument in such a way that the direction of movement coincides with the direction of rotation of the circle.

When cutting, it is important to ensure the correct position of the Bulgarian. The cut line should pass by the operator, and not to rest in it. In this case, when the circle is seized, the reactive movement of the tool will also pass aside.

The protective casing must be between the circle and the operator. Only in this case it provides reliable protection.

When cutting, you need to avoid the strong force of pressure on the grinder. It is necessary to enable the tool to exercise "on their own". Overload leads to the pumping of the circle and the risk of jamming with a reverse impact. The task of the operator is to correct the tool, slightly clicking on it in those places where it is necessary.

When cutting profiles, the cut should begin on the smallest cross section.

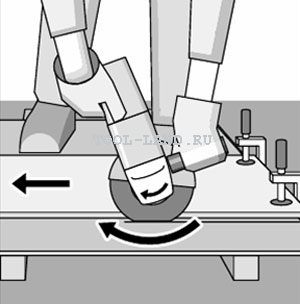

You can not turn on the tool if the circle is in propylene.

For grinding it is impossible to use too thin cutting circles. You can not polish the side surface of the cutting circle, which is not intended for work. Circles are not designed for significant lateral efforts and can break. Grinding should be kept the edge of a circle, inclined at an angle from 15 to 40 degrees to the plane of grinding. In this case, the tool moves with moderate pressed back and forth. During the start of using a new disk, do not work with a tool in the direction (b), otherwise it will stay in the workpiece. After the edge of the disk is rounded, it can also be used in the direction (A), and in the direction (b).

![]()

Cutting Bulgarian concrete, tiles, stone. Cutting concrete, tiles or stones need to be performed by special circles designed to work with these materials. With cutting of these materials, a lot of dust is formed, which is harmful to health. In strokesov, a more closed protective cover with a nozzle for connecting a vacuum cleaner is made to remove dust.

If the dust suction is not possible, it is necessary to use the respirator with the filter of class P2. You can also suppress dust using a jet of water directed to the cut, use the air ventilation.

It is necessary to be especially careful when performing cuts of walls in which various pipelines can be, electrical cables and fittings. If you get a disk on them, a reverse strike may occur. Damage to the circle of electrical wires can cause a short circuit, random cut of the gas pipeline can lead to an explosion. Before working in unfamiliar places, it is necessary to study them for communications.

Return strike. The main danger during the work of the Bulgarian represents the reverse strike - a sharp and sudden garbage of the tool as a result of jamming the rotating circle in the workpiece. At the same time, there is often the destruction of the circle.

According to the laws of physics, the reactive movement of the tool occurs in the direction opposite to the rotation of the disk. Reverse blow is usually consequence of the operator error. Prevent it or avoid severe consequences if he still occurred, certain precautions will help:

- It is necessary to keep the tool with two hands. For this, standard handles must be used.

- The body should occupy a stable position. This will help to withstand the power of the reverse strike.

- It is necessary to be located away from the place where the tool will shift when reverse impact. If the cutting circle is "from ourselves", in the case of a reverse strike, the power tool can bounce directly on the operator.

- Processing the corners and sharp edges, you need to exercise special caution and be prepared for possible tool tools. Especially often the reverse strike occurs at the end of the cut, when the last jumper connects the individual parts of the workpiece. In this case, it is recommended to avoid reverse impact, without bringing the cut to the end, remove the circle and carefully cut the jumper on the other side.

- When jamming, you need to turn off the tool and remove it from the propyl.

Special Safety Requirements. The rules for working with the Bulgarian suggest a number of requirements that, although not directly relate to the operations themselves, cutting and grinding, are very important.

Near the working area there should be no flammable liquids and gases, combustible materials: fuel, solvents for LKM, vet, etc.

It is necessary to remove materials and products that may suffer from sparks and splashes, in particular, plastic and ordinary glass, which, after hitting the sparks, unsubscribed traces remain. If you can not remove them, you need to cover with some suitable material (for example, a wet rag).

When using a grinder in the raw room or outdoor in high humidity conditions, it is necessary to connect it through the RCD to prevent electrical shock.

It is impossible to trust the work with the ears of unauthorized people, if there is no confidence that they have sufficient qualifications for safe operation. Access to the baccake of children should also be excluded.

Experiment of the Split Circle Shard when working

When using the content of this site, you need to put active links to this site visible by users and search robots.